Hello Engineers and 3D Printing Enthusiasts!

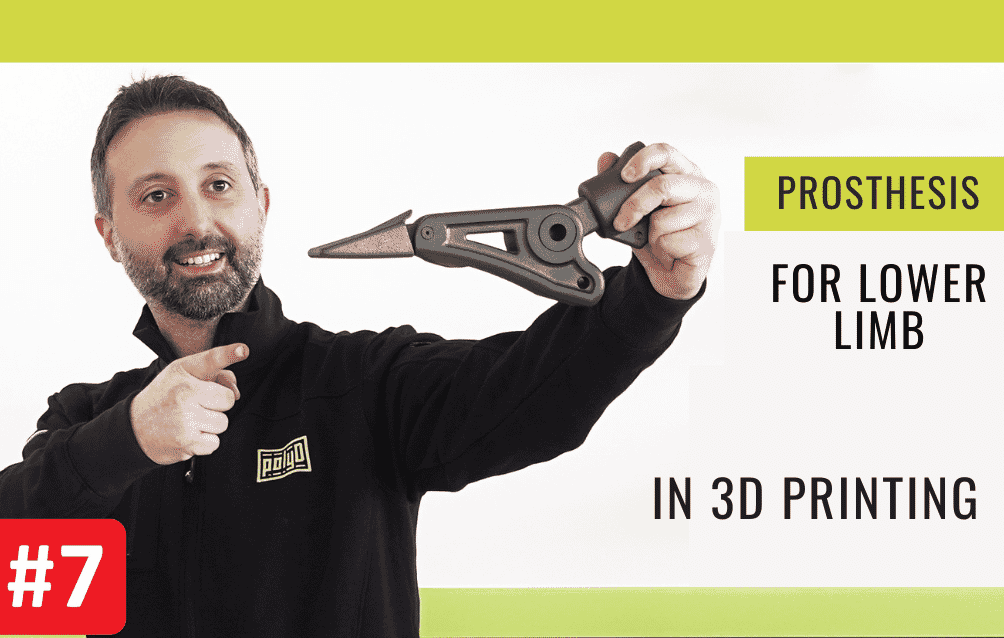

As you have already seen from the title, in today's episode we show a prototype of a Lower Limb Prosthesis made by 3D Printing.

And it's all done in the PolyDlab, the MJF Professional 3D printing technical lab, where we analyse 'extreme' projects sent in by our followers and customers, and then 3D print those that have competed, according to 5 simple evaluation criteria.

To learn more about Polydlab you can read previous articles, which we summarise here:

- what polyDlab is

- #1 Fan without blades, 3d printed

- #2 Electric Skateboard Pieces

- #3 Military Mobile Phone Holder

- #4 Motorcycle Mobile Phone Adapter

- #5 Multifunctional 3D printed prosthesis

- #6 Electronic injection for fiat 500

3D Printed Lower Limb Prototype

The 3D printed piece selected by our experts is that of Giuseppe Gamba.

It is a lower limb prosthesis, a prototype in 3D Printing. Giuseppe is a university student of Mechanical Engineering who works in design. During his studies, he took courses in prototyping external limb replacement implants, and saw that one of the main problems with these medical prostheses is the price. According to our follower, only a small fraction of patients are able to afford prostheses, despite the concessions in the health sector anyway.

This is precisely why, after becoming passionate about the cause and completing his university studies, he began designing an easy-to-make, 3D-printed lower limb prosthesis prototype to serve both companies and private individuals.

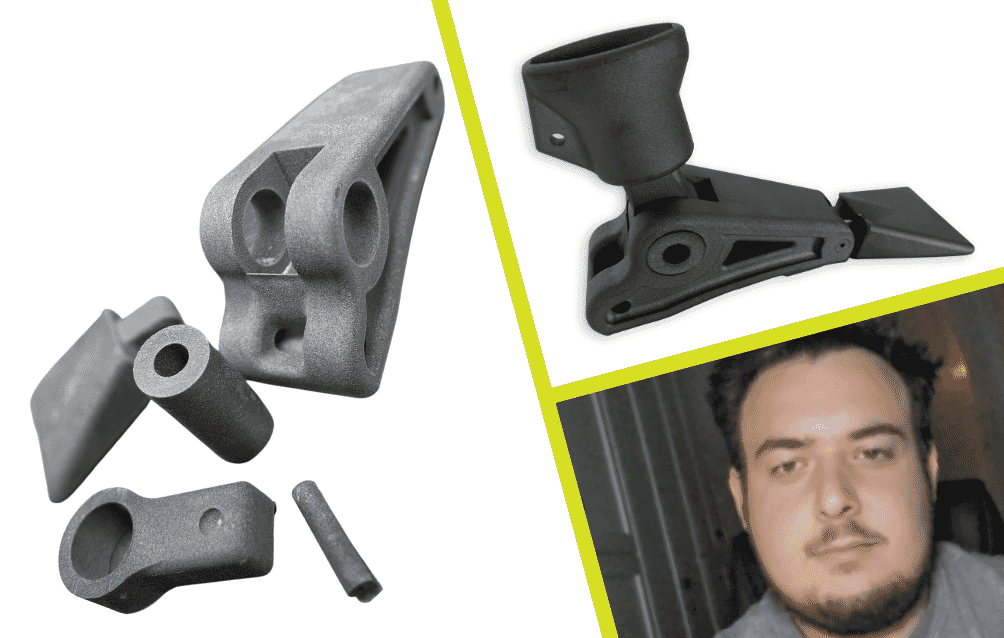

The structure of the Prototype

Giuseppe explains his project in more detail: it is a prosthesis divided into two parts; the base piece simulates the lower part of the foot and the movement of the toes, which will be constrained. The middle piece, slightly cylindrical, reproduces the ankle. Finally, the piece connecting with the upper part, conical in shape, will house two carbon bands, whose shape and profile will generate a small compression to imitate the shin. The rear part of the foot simulated in 3D will allow the insertion of a spring useful to help the movement and limit the angle.

The components were moulded in Nylon PA12 and painted in Natural Matt.

Let's look at the criteria now!

STL FILE QUALITY

The file received is really well made and the designer's expert hand is visible. This is the seventh episode of our contest and it is with great pleasure that I can tell you that so far we have always received well-designed and well thought-out files. Congratulations engineer!

Rated 5/5

3D PRINT OPTIMIZATION

The part is massive and very robust, at first glance it looks more like a project designed for CNC machining. Through topological optimisation of the part, the shape of the design could probably be redefined, lightening it by subtracting unnecessary material. This has no impact on the mechanical and physical properties of the part and saves on production costs.

Rated 3/5

AESTHETICS AND DETAILS

The prosthesis is well thought out and well cared for; the details present are cleverly joined and blunted. The piece, however, is very basic; Giuseppe could probably have dared a little more, pushing the aesthetics. MJF 3D printing today allows the creation of light and strong structures, with even complex details, without placing limits on the shape of the piece.

Rated 4/5

PRINTABILITY

The printability of the parts was easy, also due to the lack of excessively complex parts.

Rated 5/5

UTILITY

I would like to dwell on this criterion for a few more seconds. Giuseppe's piece is the second prosthesis we are analysing, if you remember the project of our follower Lucio, which is currently in second place. The opportunities offered by 3D printing to the medical sector are manifold and range from the creation of customised prostheses, to the reproduction of organs for educational purposes or structures for dental appliances.

These are just some of the possible and constantly evolving uses. Giuseppe's project is undoubtedly useful and deserves full marks.

Rated 5/5

Conclusions

Here is a brief summary of the marks awarded to the Lower Limb Prototype: file quality 5/5, 3D printing optimisation 3/5, aesthetics and details 4/5, printability 5/5 and finally usefulness 5/5. The final grade, obtained by summing all the scores and dividing them by the number of criteria, i.e. 5, is 4.4, which places Giuseppe's project in fourth place in the ranking.

If you want to know more about the project directly from its inventor, these are Giuseppe's references:

giuseppe.gamba509@gmail.com

As always, we would like to remind you that you too can participate in PolyDlab by sending us your application to labpolyd@gmail.com

In the meantime, if you would like to try your hand at 3D printing online, remember to use our Instant Quote!

Happy 3D printing!