Hello Engineers and 3D printing enthusiasts! Welcome to this new video.

PolyD lab is our MJF 3D Printing technical lab dedicated to printing and analysing extreme and complex designs, submitted by our followers and customers.

If you want to know more, read the articles on:

PolyD: Military Mobile Phone Holder

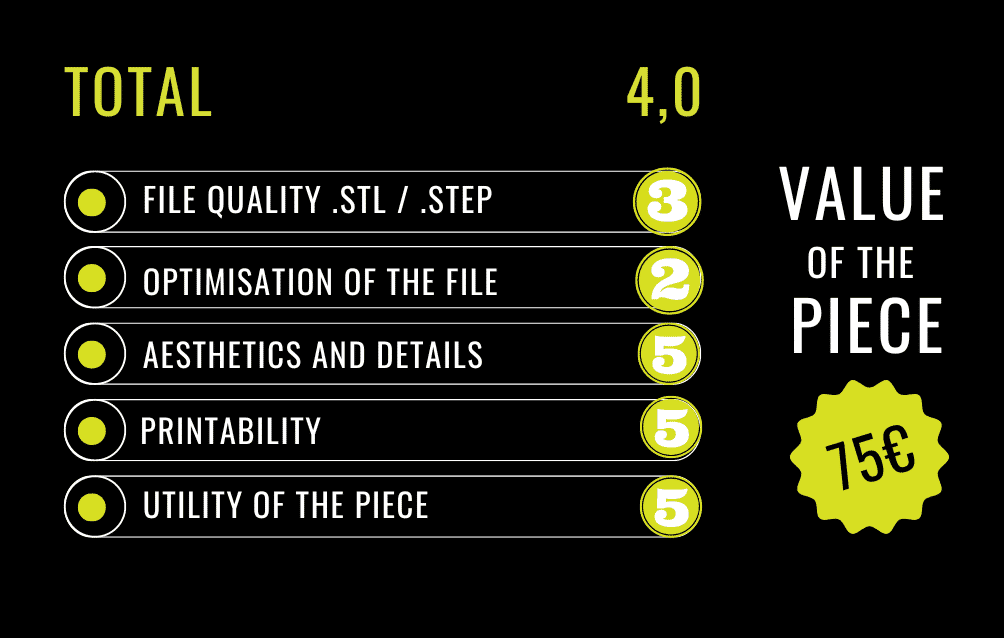

Each piece submitted for the Contest is evaluated according to 5 simple criteria:

- Resolution quality of the Stl file;

- Degree of optimisation of the 3D Print;

- Aesthetics and Details;

- Printability;

- Usefulness of the part.

To participate in the MJF 3D Printing Contest you can send your file to labpolyd@gmail.com

Our team of experts selects one project per month, evaluates it and 3D prints it online with Multi Jet Fusion technology. The resulting project is sent to the selected follower/customer's home free of charge!

We are now in the third instalment of the polyDlab Contest; this month's winning piece is by Gianmarco Amici.

3D printing of Military Mobile Phone Holder

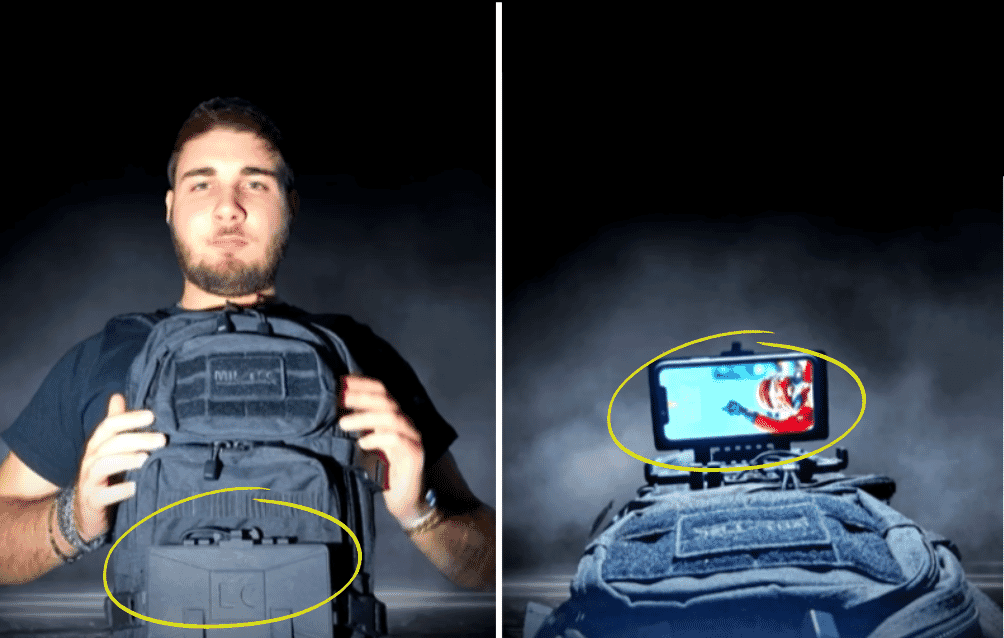

Gianmarco is a 19-year-old student with a passion for 3D printing. Gianmarco designed a mobile phone cover as a military support inserted inside a specific backpack. The piece, as Gianmarco explains, is intended for military use and stems from the need to communicate position coordinates from the mobile unit to the airborne unit. The holder attaches to the bulletproof vest and an elastic band allows it to be quickly attached and detached.

The military mobile phone cover was printed in Nylon PA12 and coloured in Natural Matt, materials constantly used for Rapid Prototyping of Objects, Components, Parts.

The team of experts evaluated the design as follows:

1. QUALITY OF THE STL FILE:

The rounded corners and more generally the curved surfaces of this object appear segmented; to remedy the problem, the file could have been exported with a higher resolution. However, the thickness of the walls in proportion to their length is excellent.

Rated 3/5

2. 3D PRINTING OPTIMISATION:

The product has been optimised for 3D printing, which can be seen by the hollowing out of some points of a component of this cover. In this way, the object is less expensive, because it saves on the material needed and still remains solid and functional.

Gianmarco designed the hinge, i.e. the joint between the two components, calculating a 0 tolerance for friction during the joint. In our view, it would have been better to leave a tenth of a tolerance on each side to ensure an excellent fit and at the same time easier interlocking.

Rated 2/5

3. AESTHETICS AND DETAILS:

The object has been meticulously detailed; on the front, for example, we find the initials of the soldier who is to use this cover, while on the inside we can see a motif composed of many repeated hexagons. It is interesting that the designer has thought of limiting the opening of the cover to 90 degrees and of not providing sharp parts that could have been dangerous during movement.

Rated 5/5

4. PRINTABILITY:

Here I have very little to say. The printing is excellent, the surfaces are strong and there are ribs in the right places.

Rated 5/5

5. UTILITY:

Gianmarco in his presentation video explained very well the usefulness of this piece and as you could see the product fits perfectly into the military backpack. It was really exciting to see and touch this guy's commitment to meeting a need with Multi Jet Fusion 3D printing. Bravo Gianmarco!

Rated 5/5

Conclusions

Let's summarise the grades assigned to Gianmarco's Military Mobile Phone Cover:

- file quality 3/5,

- 3D print optimisation 2/5,

- aesthetics and details 5/5,

- printability 5/5

- utility 5/5.

The final grade, obtained by adding up all the scores and dividing them by the number of criteria, i.e. 5, is 4. The cover ranks second.

If you want to know more about this project, you can find Gianmarco's references here:

Follower Gianmarco Friends

amicigianmarco@gmail.com

Would you also like to try your hand at online 3D printing?

Polyd is the most popular MJF 3D printing service for professional and industrial 3D printing. Try our Instant Quote.

Happy 3D printing!