Hello Engineers and 3D Printing Enthusiasts!

Welcome to today's video which, as you have already seen from the title, is about a very interesting piece.

We are in our PolyDlab, the MJF 3D printing technical lab. In this space we analyse the 'extreme' projects sent in by our followers and customers and print those that have competed according to the evaluation criteria. In this article we discuss the Pike Multifunctional Prosthesis.

To find out more you can read the previous articles, which we summarise here:

- What is polyDlab;

- #1 Fan without blades, 3d-printed;

- #2 Electric Skateboard Pieces;

- #3 Military Mobile Phone Holder;

- #4 Motorcycle Mobile Phone Adapter.

PolyD, Multifunctional Prosthesis in 3D Printing

PolyDlab is the laboratory where we analyse projects that we print for free. You too can participate by sending your .STL file labpolyd@gmail.com

Please note that the analysis is carried out by evaluating 5 simple criteria:

- Resolution quality of the Stl file;

- Degree of optimisation of the 3D Print;

- Aesthetics and Details;

- Printability;

- Utility of the part.

3D Printing of the Multifunctional Prosthesis

The piece selected by our experts is that of Lucio Buricca.

Lucio is a 35-year-old guy who founded a company that produces glasses with magnetic hinges whose temples release if they are subjected to excessive pressure. Specifically, Lucio does the design work, together with his brother.

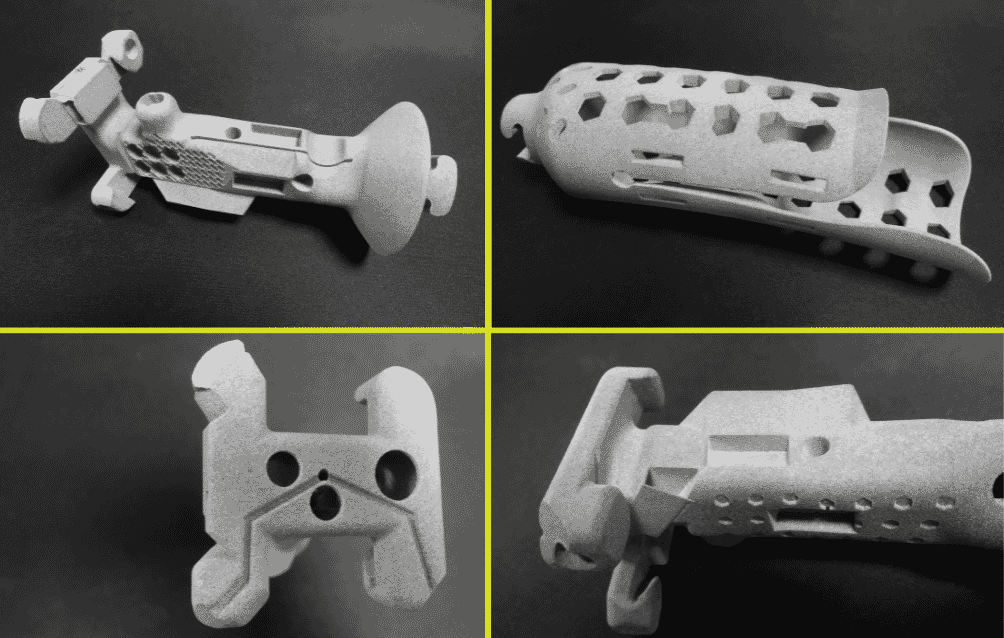

Lucio wanted to participate in our contest with a very special project: it is a prototype of a multifunctional prosthesis, consisting of two parts:

- the socket, which is the upper part, fitted with two fins that allow it to be widened and tightened;

- the appendix, which is specifically the multifunctional part.

The piece designed by Lucio was moulded in Nylon PA12.

As with each instalment of this contest, we proceed with the analysis of the 5 criteria on the basis of which Lucio carried out the Rapid Prototyping of the piece.

1. QUALITY OF THE STL FILE

The file we received is really well made, the moulded parts are well joined and chamfered. Most probably the project is so well done because this is not a first release; in fact Lucio has previously printed the project using FDM technology.

VOTE 5/5

2. 3D PRINTING OPTIMISATION

As we said, these parts were born to be printed with FDM technology, but Lucio then made some modifications to make it more suitable for MJF 3D printing. You can see this, for example, from the holes in the base of the appendix; the holes are used to release the unmelted powder, which accumulates inside the object during production. In addition, Lucio used a programme to help with the emptying of the parts.

The only point we would like to make is this: the pot could have been designed with less thickness, to make the part less rigid. It would have been better to produce this prototype with TPU, to increase the comfort of use.

Rated 4/5

3. AESTHETICS AND DETAILS

The dovetail joint between the two components is really well made; the tolerances are perfect. Also noteworthy is the very thin slit in the appendix; it is a gap of about 7 tenths. Also particularly interesting are the polygonal patterns, which enhance the price grip.

In addition to the holes to lighten the Prototype and allow more air to pass through, the socket is also designed with two small slits that allow the passage of Velcro laces, laces that tighten the prosthesis around the forearm.

Rated 5/5

4. PRINTABILITY

The print succeeded perfectly.

Rated 5/5

5. UTILITY

This is the most interesting point. Starting from the upper part of the appendix we see that it is funnel-shaped, to prevent the sleeve of the shirt falling down, which would cover the piece. Immediately below we find the space for attaching a smartwatch; this slot serves to carry the finger pointers. The holes in the front serve for the use of the same finger-prick hands; the pockets at the base allow the insertion of magnets, so as to allow the use of a smartwatch (inside which is a metal plate).

The magnet on the side of the appendix, on the other hand, allows the use of cutlery.

The channels on the bottom are used to insert a small electrical wire, which makes contact with a passive capacitive pen. When the prosthesis is worn, contact with the skin activates the pen on the upper side.

Kudos to Lucio for his ingenuity!

Rated 5/5

Conclusions

The following is a summary of the marks awarded to this project: file quality 5/5, 3D printing optimisation 4/5, aesthetics and details 5/5, printability 5/5 and finally usefulness 5/5. The final grade, obtained by adding up all the scores and dividing them by the number of criteria, i.e. 5, is 4.8.

Lucio's work thus takes first place in the rankings, overtaking the fan.

If you would like to know more about the multifunctional prosthesis prototype, you can write directly to:

Lucio Buricca

email: lucio.buricca@gmail.com

If you then feel like 3D printing Prototypes, Parts and Components, try the Instant Online Estimator: in 1 second you get the quote.

And the first order is free.

Happy 3D printing!