Hello Engineers and 3D Printing enthusiasts!

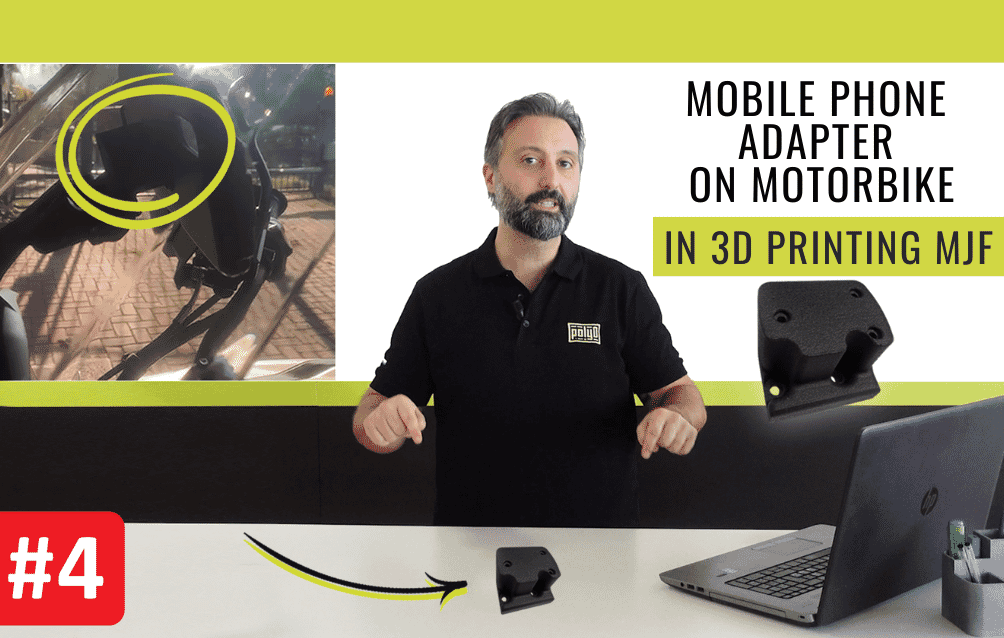

Welcome to today's video. We are in the PolyD-Lab, our MJF 3D Printing technical lab dedicated to printing and analysing extreme and complex projects sent in by our followers and customers! In this article, we talk about Antonio's Mobile and Motorcycle Holder Adapter.

To learn more, you can read the previous articles:

- what is the polyd lab

- #1: 3D printed bladeless fan

- #2: electric skateboard parts

- #3: military mobile phone holder

PolyD 3d printed motorbike mobile phone holder adapter

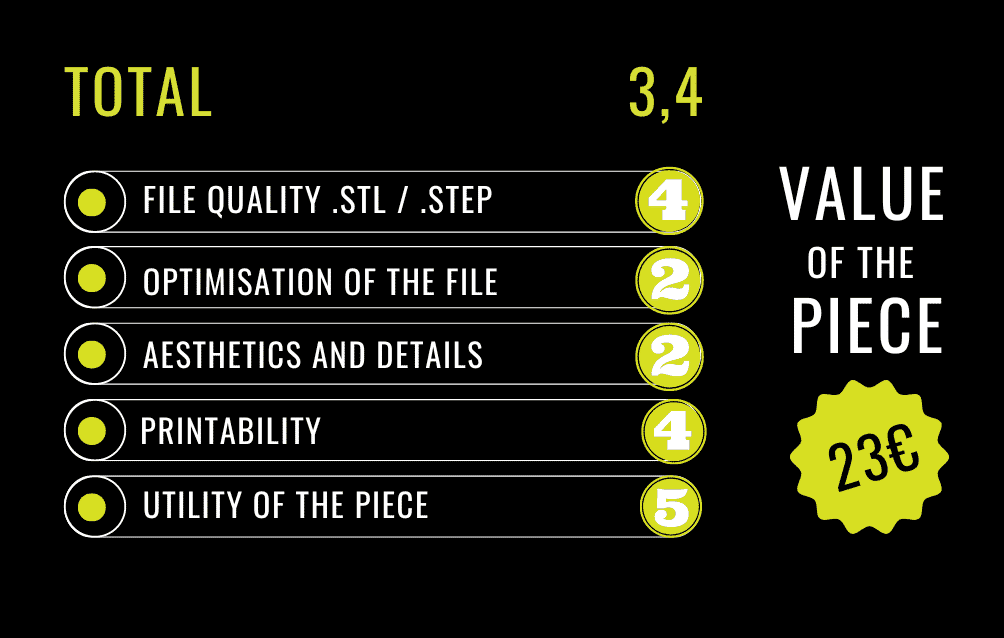

The design is analysed by evaluating 5 simple criteria:

- Resolution quality of the Stl file;

- Degree of optimisation of the 3D print;

- Aesthetics and Details;

- Printability;

- Usefulness of the part.

If you want to try your hand at printing and analysing your Part, Prototype or Component send us the file to labpolyd@gmail.com

Our team of experts will select one per month; the printed part will be filmed, examined and sent to the designer free of charge!

The overall grade of the project will then enter the final ranking, updated month by month.

3D printing of the Motorcycle Cell Phone Holder Adapter

The piece selected by our experts is that of Antonio Pacelli.

Antonio is a follower of ours with a passion for motorbikes who had a very specific need, namely to transform his motorbike navigator holder into a mobile phone holder. To do this, he needed a part that would act as a link between two accessories of different brands, namely the navigator holder and the mobile phone cover.

The piece designed by Antonio was printed in uv-resistant black coloured Nylon PA12.

1. QUALITY OF THE STL FILE:

The STL file received is well designed and exported correctly. We can see this from the curved parts of the part, which are smooth and without segmentations.

Rated 4/5

2. 3D PRINT OPTIMISATION:

Antonio needed to produce a single part that would guarantee mechanical strength and performance over time; what better technology than Multi Jet Fusion 3D printing?

The same CNC-printed part would have cost much more, due to the high set-up costs. However, this part was not 100 per cent designed for the best saving: some of the internal parts could have been hollowed out to save material, lighten the part and maybe make up a few tenths of a second on the track lap!

Rated 2/5

3. AESTHETICS AND DETAILS:

The piece aims more at the concrete than the aesthetics.

Rated 2/5

4. PRINTABILITY:

Although massive, this component does not present any printing problems, as it is small in size. If it had been larger, there might have been problems with hollows.

Rated 4/5

5. UTILITY:

In the video, our follower Antonio explains at length how the piece is useful and functional.

Rated 5/5

Conclusions

Here is a brief summary of the grades awarded to this project:

- file quality 4/5,

- 3D printing optimisation 2/5,

- aesthetics and details 2/5,

- printability 4/5

- finally utility 5/5.

The final grade, obtained by adding up all the scores and dividing them by the number of criteria, i.e. 5, is 3.4.

Antonio is currently in last place in the ranking.

If you want to know more about this component, we leave you Antonio's references:

Antonio Pacelli

antoniopacelli@hotmail.it

Do you want to try your hand at 3D printing? Polyd is the fastest and most accurate online 3D printing service on the market. Quote your Part online now.

Happy 3D printing!