Hello Engineers and welcome to this new article!

Today we are going to show you how the Fan without Blades, a special printed fan designed by Valerio Canulli, was made in the PolyDlab Contest.

Are you curious? Let's start the journey together.

PolyDlab: MJF 3D printed bladeless fan

Before telling you about Valerio's project, should you also be interested in taking advantage of the initiative, let us remind you what PolyDlab is and what the Contest consists of.

PolyDlab

PolyD is MJF's online 3D printing service and provides a functional, fast and cost-effective 3D printing service. PolyDlab is our technical lab dedicated to the realisation of your extreme and complex rapid prototyping objects. In this lab, we test the limits of Multi Jet Fusion 3D printing with industrial and professional printing projects from our customers and followers, providing the technology, skills and experience of PolyD technicians! All this for those who participate in the polyDlab contest.

PolyDlab Contest

Every month, polyDlab chooses a piece that takes 3d printing to the extreme and meets the 5 criteria required by the evaluation team. The Contest is completely free of charge and to participate, simply send an STL file to labpolyd@gmail.com

Our experts will evaluate 1 per month, which will be printed and sent free of charge to the designer of the Piece.

Find out how to participate by reading our article on PolyDlab.

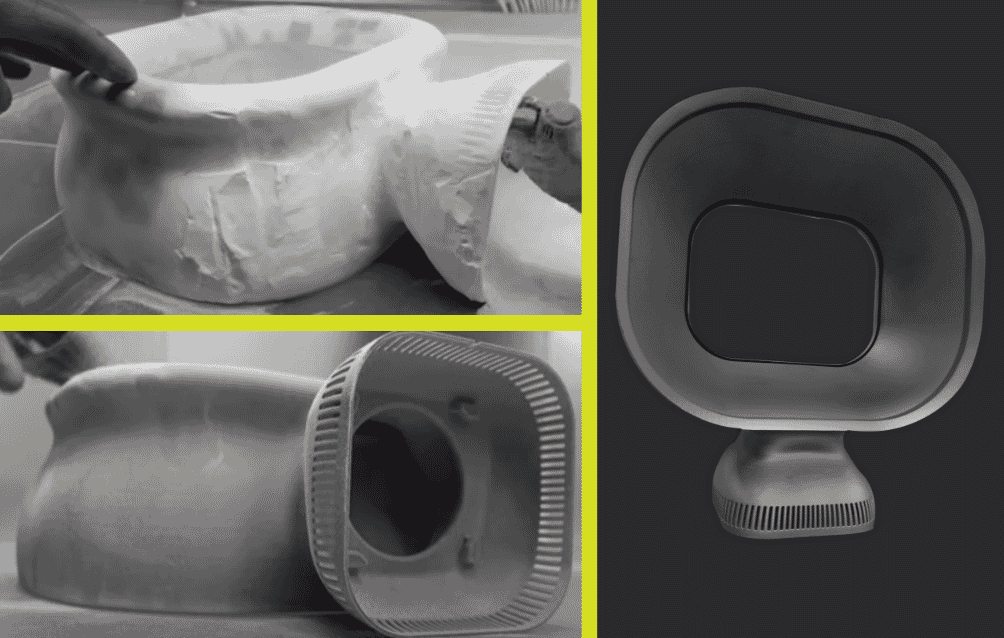

THE FAN PRINT

The part selected by our experts is that of Valerio from Rome. Valerio is a mechanical designer who has been passionate about 3D printing for more than 10 years and wanted to participate in our contest to put MJF 3D printing to the test by designing a one-piece bladeless fan. Valerio claims that this type of bladeless fan multiplies the airflow by 15 times, making it much more efficient than a traditional fan. Moreover, it does not require any screws: our follower has designed a joint at the base of the fan precisely to insert an 80mm fan that he bought on the Internet. The piece is moulded in Nylon PA12, sandblasted and UV-resistant coloured!

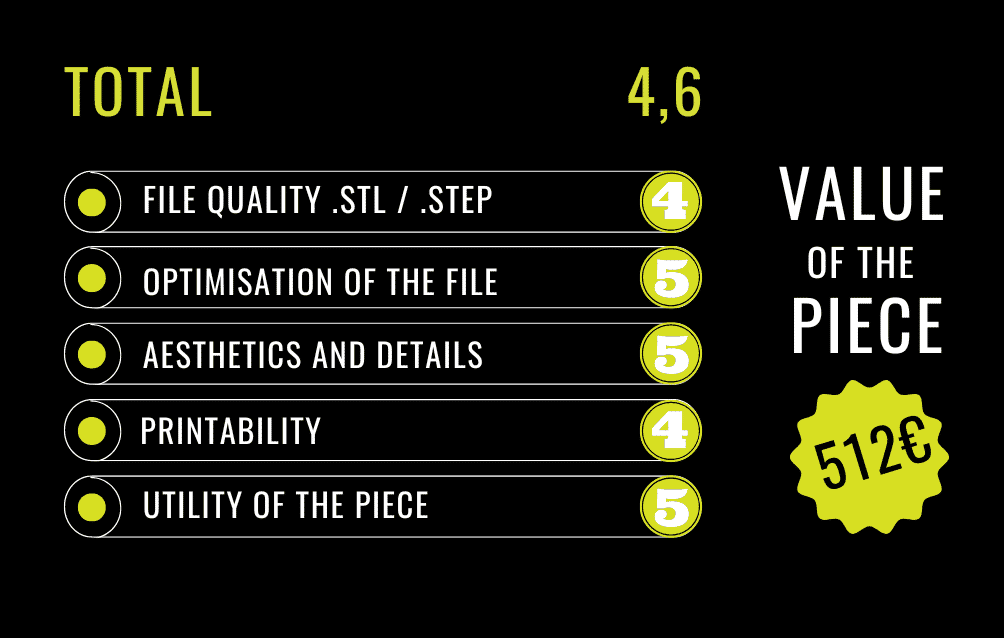

Valerio's piece was evaluated following 5 CRITERIA:

1. QUALITY OF THE STL FILE

The STL file received is undoubtedly well made and this can also be seen by the presence of a flat and smooth surface in the fan walls. The file arrived in STL format. For such voluminous products, it would have been better to send a STEP file in order to always get the best resolution when printing.

Rated 4/5.

2. OPTIMISATION OF 3D PRINTING

The project was designed to be 3D printed. Being a monoblock, it would be unfeasible with injection moulding. The interlocking of the fan with the internal housing avoids the need for screws and makes the fan, obviously after being printed, a plug and play product.

Rated 5/5.

3. AESTHETICS AND DETAILS

The fan turns out to be a design object, very minimal, but nevertheless elegant and without frills.

One detail worth mentioning is the half-moon at the base of the fan, which is designed to allow the fan's usb cable to be pulled out conveniently.

Rated 5/5.

4. PRINTABILITY

The surface quality is very good, the sizing of the walls is correct and provides excellent product strength.

A limitation of the process is the deformations at the base, due to the high ratio of length to wall thickness. One idea to eliminate this defect could be to make internal ribs or a different geometry to strengthen the walls.

The printer was also able to print the sharpest part of the front frame, let's say that it would have been better to make a small joint to avoid the possibility of chipping. The designer probably wanted to prioritise design.

Rated 4/5.

5. UTILITY

The design of the fan arrived in the summer: as never before does everyone understand its usefulness!

Vote 5/5.

Conclusions

In closing this first instalment, let's make a brief summary of the grades awarded to Valerio's Fan:

- File quality 4/5

- 3D printing optimisation 5/5

- Aesthetics and details 5/5

- Printability 4/5

- Utility 5/5

The final grade, obtained by adding up all the scores and dividing them by the number of criteria, i.e. 5, is 4.6.

Not bad at all for being the first episode!

We thank Valerio for participating in our MJF 3D Printing Workshop and for his feedback!

Follower Valerio Canulli

valerio@free-ware.it

If you too would like to experience the quality of our online 3D printing, please visit our website and try our Instant Quote.

Happy 3D printing!