Good morning Engineers!

Today we are in the PolyD-Lab, our MJF 3D printing lab, to tell you how we decided to take on a challenge as interesting as it is complicated, namely to print the world-famous Super Mario KART in 1:1 scale in less than 3 weeks!

We threw ourselves into this challenge with enthusiasm, aware from the outset of how little time we had available and how much work there was to be done!

Super Mario Kart in MJF 3D Printing

Super Mario Kart is a famous racing video game developed by Nintendo. First launched in 1992, the game has won the hearts of millions of players worldwide. Super Mario Kart offers a frantic driving experience with characters each with their own special abilities. It has become an icon of the video game world and has left an indelible mark on gaming history.

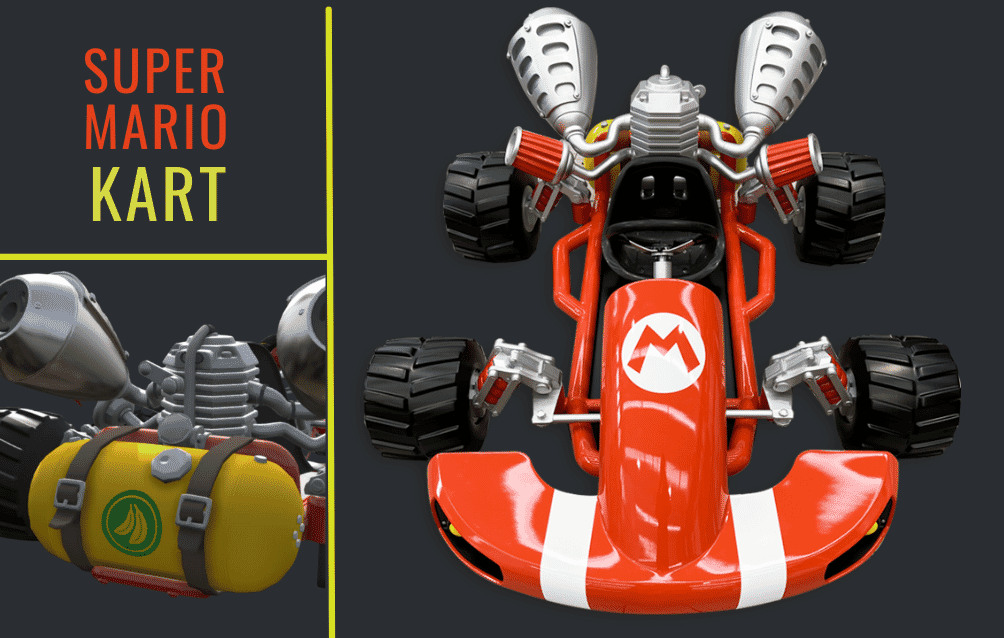

The car, precisely the Super Mario Kart, was to be presented at one of Italy's most important theme fairs, Romics 2023, with the aim of promoting the Super Mario Bros. film that was to be released at the beginning of April.

The Steps of Realisation

Once the initial euphoria had passed, we immediately thought about the best way to approach the realisation of the Prototype. As you may have already read in our blog or listened to our videos, the realisation of objects in online industrial 3D printing consists of several steps, which we went through in the realisation of this impressive project: the design of the build and the control of the file and its dimensions, the printing phase, cooling, unpacking and sandblasting, colouring and painting.

1. Designing the build, checking the file and dimensions

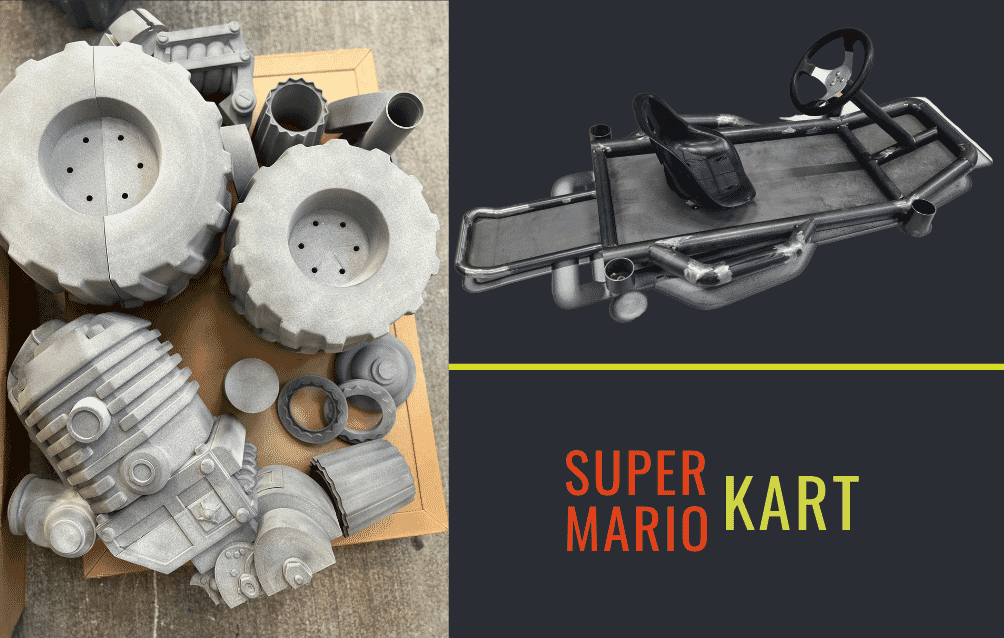

The critical issue immediately visible to the technicians was the lack of the required fasteners, joints and joins to make the assembly of the various components feasible and convenient. The files were therefore adapted for the purpose. The size of 2.3 x 1.6 m would not have allowed printing in one go, as in MJF 3D printing the print area is 38x28x38 cm. The problem was solved by splitting the oversize parts.

The design of the build allowed the different parts to be organised and prototyped quickly and precisely. During the analysis of the 3D print file, the geometry, dimensions and correctness of the model were checked in order to detect any errors or problems that could jeopardise the print and in this case added the necessary fasteners, joints and joins. The size of the 3D MJF print required the model to be broken down into smaller parts, which partly affected the production time.

2. 3D Printing

Individual parts were nested in nested builds and 3D printed. MJF 3D printing allows parts to be produced 10 times faster than other 3D printing technologies, with extreme precision. At the end of the printing phase, the parts were cooled in the Natural Cooling station, with 48 hours stationary, to achieve the best mechanical and aesthetic results of the parts and minimise bending and deformation. Finally, the unmelted powder was removed and sandblasted.

3. The Chassis and other small components

The chassis of the car had to be able to support the entire structure and withstand continuous stress. The aim of the kart was not just aesthetic; the main objective was to make the fans experience the thrill of sitting inside the kart and taking a souvenir photo. To realise this, we turned to a machine shop that was able to create the steel chassis from a flat print.

We then sourced the components on the market that could not be reproduced with 3D printing or that would not do justice to the design, namely the steering wheel and the belts.

4. Treatment, Sanding and Painting

The larger components, such as the fairing, were printed in blocks and then reassembled. They required sanding, filling and priming and painting to completely eliminate the joints. The last step before assembly was to paint each piece in its original colour. All pantone painting was carried out in a controlled dust chamber to avoid dirt, drips and imperfections that could have compromised the aesthetic result. The process used is the same one we use for the industrial and automotive sectors.

Conclusions

It was exciting to take on this challenge and even more exciting to complete it in the required time. Congratulations to the entire PolyD Lab team!

If you also want to try your hand at 3D printing, take advantage of our Free First Order offer.

Happy 3D printing to all!