Hi Engineers,

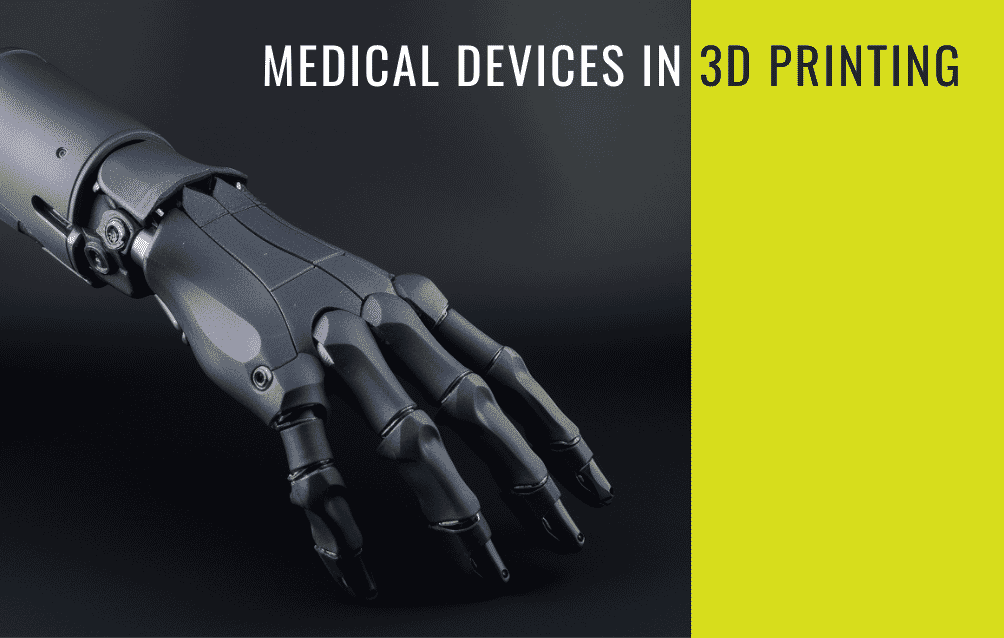

Today we are talking about the medical device industry that provides the essential tools for the diagnosis, treatment and monitoring of diseases and that, thanks to technological innovation, improves the quality of medical care and wellbeing solutions for patients.

PolyD, Medical Devices in 3D Printing

Industrial 3D printing with Multi Jet Fusion has opened up more and more perspectives in rapid, customised and high-precision design and prototyping for the medical device industry, such as orthopaedic medical devices for wrist, elbow and knee.

As a 3D MJF printing service, PolyD relies on a layered printing process, in which a fixing agent is applied to a thin layer of thermoplastic powder. Subsequently, a fusing agent is sprayed onto the same layer to selectively fuse the particles at the desired areas. The process is repeated layer by layer until the final object is completed.

The advantages of using 3D printing

Competition in this sector is high due to the presence of numerous companies developing and marketing innovative devices. This is good for the research and development of new technologies and solutions and makes it possible to offer increasingly safe, effective and efficient devices, provided that the right choice of 3D printing partner is made online. Due to its special nature, MJF 3D printing is ideal and offers numerous advantages.

1. Customised Complex Medical Prosthetics

First of all, it allows the fabrication of custom-made prostheses and components according to the patient's anatomical specifications. The result is a better fit and comfort, and consequently an improved quality of life for patients.

The fabrication of custom-made prostheses by professional 3D printing is revolutionising the medical sector. This technology makes it possible to create customised prostheses based on the specific needs of each patient. Using 3D scanners, anatomical data is captured with millimetre precision to create a perfect replica of the limb or organ to be replaced. 3D printing allows greater design flexibility, enabling the functionality and comfort of the prosthesis to be optimised. Thanks to this innovation, patients can enjoy greater mobility and quality of life, with parts that perfectly fit their body and individual needs.

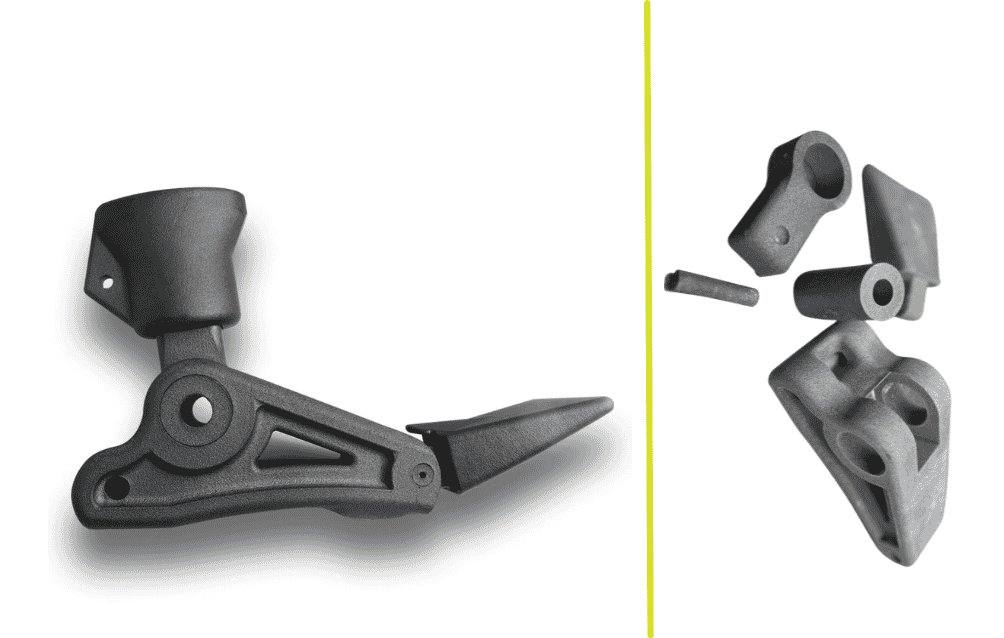

Furthermore, thanks to the millimetre precision achieved by MJF technology, it is possible to produce complex parts that often facilitate the work of doctors. The ability to print parts with complex geometries allows for more functional and efficient devices, reducing the need for multiple assemblies and enabling greater integration of functions.

Example of a Lower Limb Prototype, made by Giuseppe Gamba. If you want to know more, read our blog article.

2. Biocompatible Printing Materials

Another significant advantage of MJF 3D printing for medical devices is the possibility to use biocompatible materials. Thanks to the selection of materials that are safe for the human body, it is possible to produce Parts and Prototypes that do not cause adverse reactions or complications in the patient, guaranteeing their safety and effectiveness. The biocompatibility of 3D printing materials is ensured through rigorous testing and evaluation of their toxicity and interaction with biological tissues; these materials offer a combination of desirable properties such as mechanical strength, flexibility and chemical stability, guaranteeing adequate functionality of the devices.

Nylon PA12 (polyamide 12) is a biocompatible material widely used in 3D printing for the production of medical devices. Due to its high mechanical strength and chemical stability, PA12 is an excellent option for the creation of high-quality prostheses and components. The versatility and properties of PA12 make it an ideal material for 3D printing customised and safe parts, prototypes and prostheses.

It is important to emphasise that biocompatible materials must be used in accordance with regulations and quality standards, ensuring the safety and effectiveness of medical devices.

3. Reduced 3D printing times

MJF 3D printing also offers reduced production times compared to traditional methods. With the elimination of special tooling and moulds, preparation and production times can be reduced, enabling rapid delivery of customised medical devices. This is especially crucial in emergency situations or when a quick response is required to meet patient needs.

4. Reduced Production Costs

Finally, MJF 3D printing can also help reduce the cost of manufacturing medical devices. The ability to make complex parts in a single printing process, without the need for assembly or subsequent machining, can reduce labour and material costs. In addition, the elimination of the costs of special tooling or specific models results in significant cost savings.

Example of a multifunctional prosthesis made by Lucio Buricca. If you want to know more, read our blog article.

Conclusions

MJF 3D printing is revolutionising the medical device industry with its ability to produce customised, complex and biocompatible solutions. This technology opens up new perspectives in the design and production of medical devices, enabling more efficient, safe solutions.

Try PolyD and take advantage of the Free First Order offer!

Happy 3D printing!