Hi Engineers!

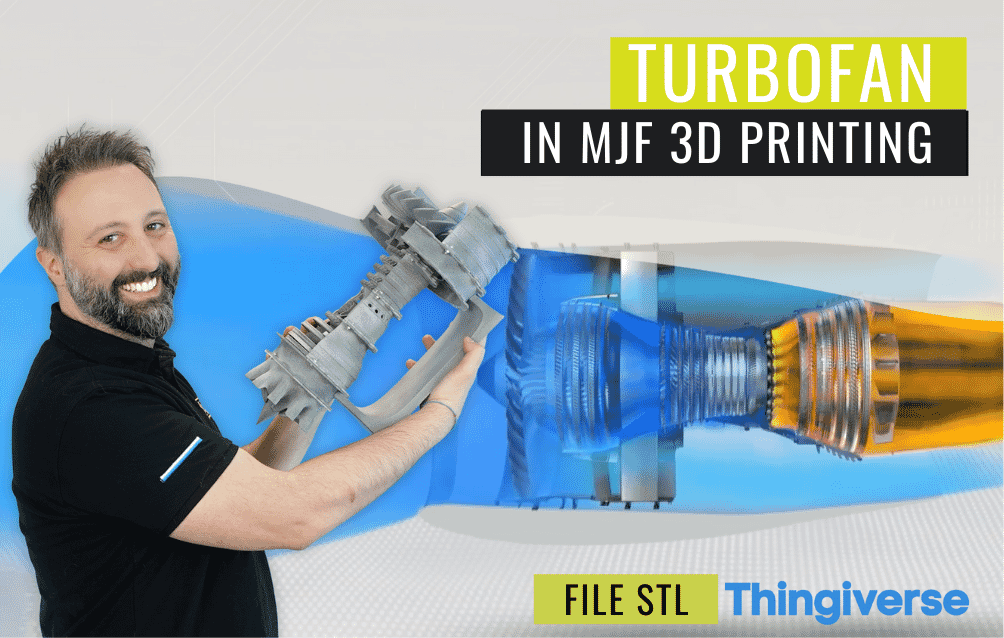

Here we are with a new video showing a 3D printed part with MJF Technology, one of the best 3D printing technologies currently on the market, using Nylon PA12 as material. This is the Turbofan, a type of jet engine.

3D PRINTING MJF: THE TURBOFAN

In this video, after a brief explanation of how the Turbofan works, we show you how professional MJF 3D printing is done.

- We start with the project, an STL file downloaded from Thingiverse;

- We then proceed with the Rapid 3D Printing with MJF Technology;

- Finally, we mount and assemble the parts.

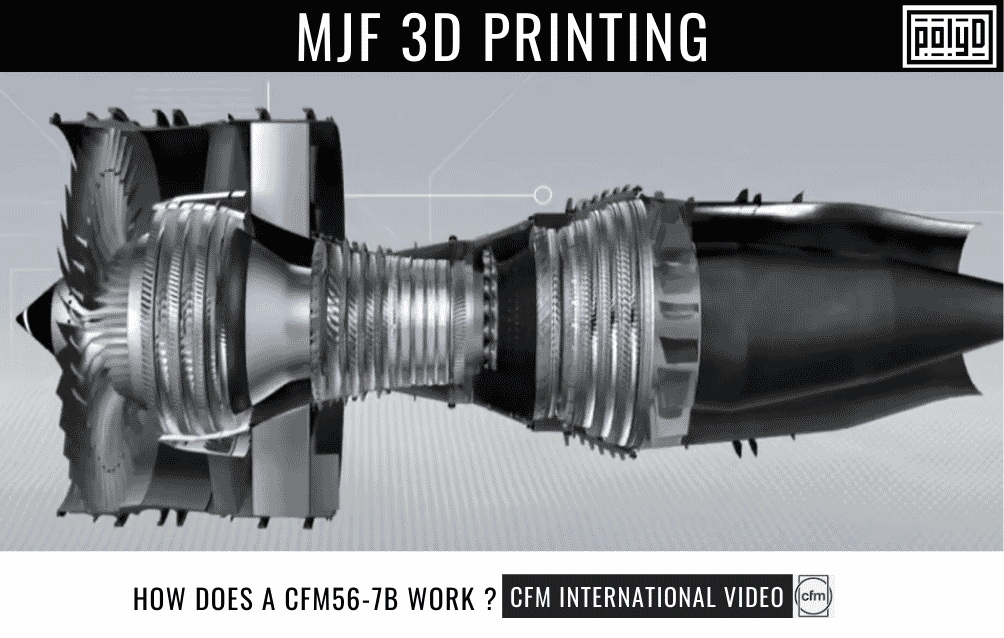

What is a Turbofan?

A turbofan is a type of jet engine used on most airliners. In order to move the aircraft, it sucks in air and forces it out the back, after it has passed through the turbofan via two streams:

- a central one, in which the air is heated by the movement of the smaller fans;

- a peripheral flow in which the air passes through the largest fan and remains cold.

In the central flow the air is heated by compression: it passes through smaller and smaller fans and reaches a temperature of about 450 degrees.

In the combustion chamber, the contact of the air with the fuel raises the temperature to around 1,700 degrees. This creates the energy needed for the air to escape from the turbine and rotate the central shaft, which is connected to the fan at the front of the engine, from which the cold, peripheral airflow enters.

If you want to learn more, listen to CFM International's video on how a CFM56-7B turbofan works.

MJF 3D Printing

To get the STL file for printing, we used Thingiverse.com, one of the most popular file sharing and download sites for 3D printing, which we have already mentioned in the article 5 free modelling software for 3D printing. On the site there is a search engine in which we typed the word Turbofan and selected the project we were most interested in.

On the landing page, in addition to the classic buttons for downloading files, there are also useful information such as comments and images from other users who have already printed or even modified versions of the file.

HP Professional 3D Printers with Multi Jet Fusion (MJF) technology transform old handcrafted production into Parts and Prototypes with light, strong structures and no shape limits; they are therefore excellent for the production of parts with high levels of quality. They work in the same way as inkjet printers, so they have excellent precision and in addition 10 times the speed of laser sintering. If you want to learn more about the advantages of MJF 3D printing, read our article on the 3 most used technologies in 3D printing: MJF, FDM, SLS.

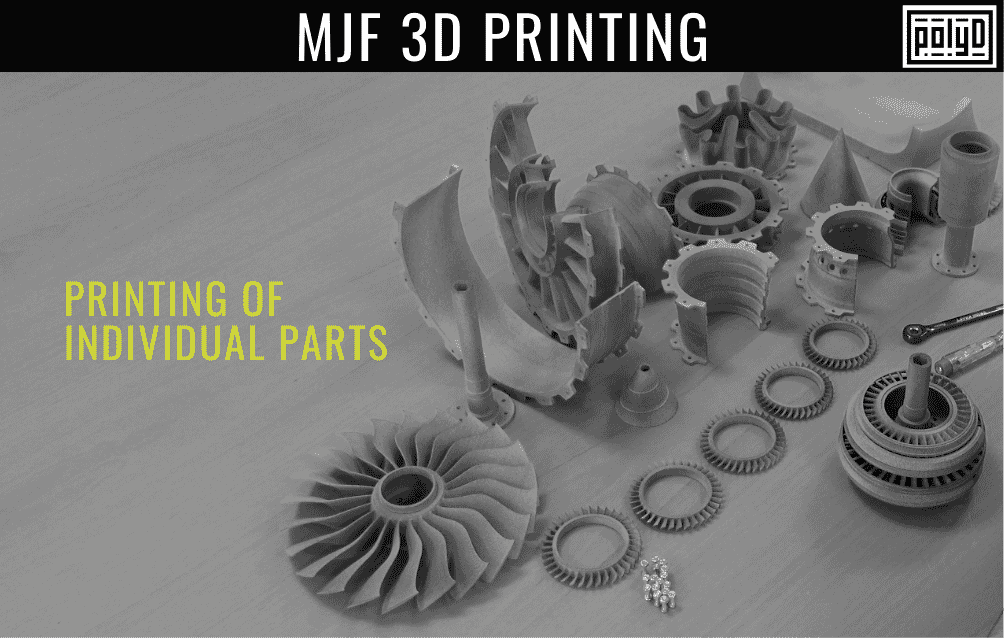

Once the STL file was downloaded, 3D printing of the individual Turbofan components was quick!

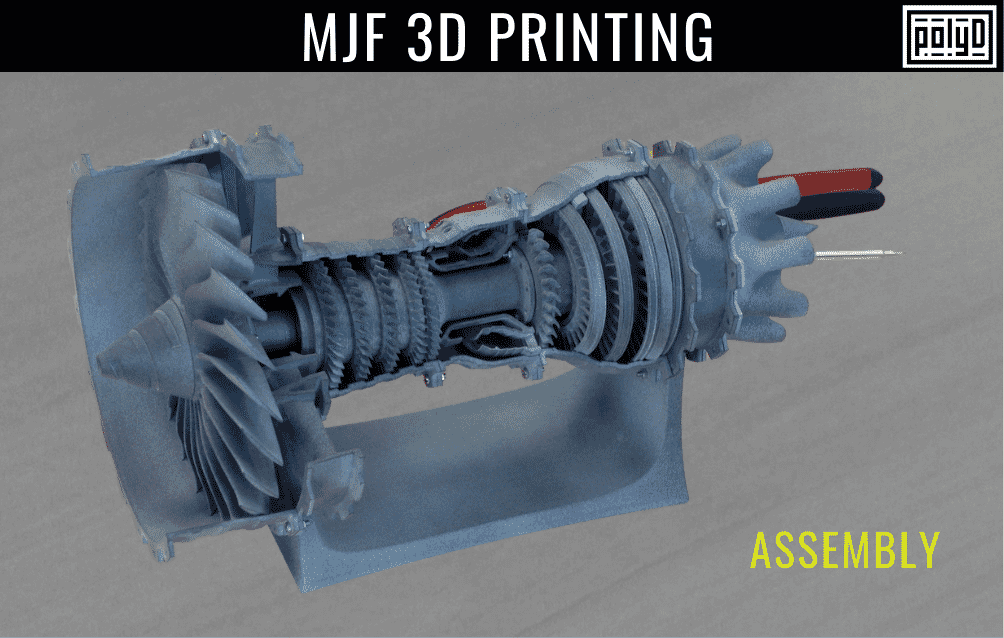

Mounting and Assembly

We have divided the printing of the turbofan into several parts. There are many techniques for assembling the components of a model.

Luca, our technician, assembled every single part of the Turbofan using standard tools, such as screwdrivers, pliers and M4 screws, which can be easily bought in any hardware store. The result of his work is visible below, a perfect MJF 3D Printed Prototype using Nylon PA12 as material.

If you want to try your hand at MJF quality 3D printing of your own Parts, Prototypes and Components, use our Instant Online Quote!

Happy 3D Printing!