Hello Engineers!

Today we are talking about

There are various methods for printing online a 3D object, each with its own merits and limitations. The most commonly used printing techniques on the market today are FDM (Fused Deposition Modelling), SLS (Selective Laser Sintering), MJF (Multi Jet Fusion).

The 3 most used 3D printing technologies: MJF, FDM, SLS.

A 3D printed object is developed on 3 axes, x,y,z. The x and y axes create the two-dimensionality and the three-dimensionality is given by z. The three-dimensional development on the z-axis is the common feature of all types of 3D printing, but they differ in the details of object construction on this axis.

FDM - Fused Deposition Modelling

Fused Deposition Modelling (FDM) is an additive manufacturing technique, which is used from CAD to produce Parts, Prototypes and for modelling applications. The thermoplastic material used for printing wound on a reel is unwound and passed through a heated nozzle that deposits it on a plate following the indications coming from the print file. The object is then created on the z-axis, layer by layer.

The main advantage of this type of printing is affordability: thanks to the low purchase price, printers and printing materials are accessible to everyone. The limits of the technology are the accuracy, which is not high, and the long printing times, which make it difficult to use in mass production.

SLS - Selective Laser Sintering

Selective Laser Sintering (SLS) is an additive manufacturing technique: polymer or composite powder particles (SLS) or metal powder particles (SLM) are sintered using a laser beam. Unlike FDM printing, which creates objects using filaments, SLS printing uses powder, again made of thermoplastic material, such as nylon PA12. The nylon powder is spread inside a printing booth; the machine, with a special laser beam, melts the points that are indicated in the file and creates the object on the z-axis. The advantages of this type of printing are the excellent dimensional quality, greater resistance, fast production time and the invisibility of the printing layers on the object.

This 3D printing technology was the most widely used before the advent of 3D printing with MJF technology.

MJF - Multi Jet Fusion

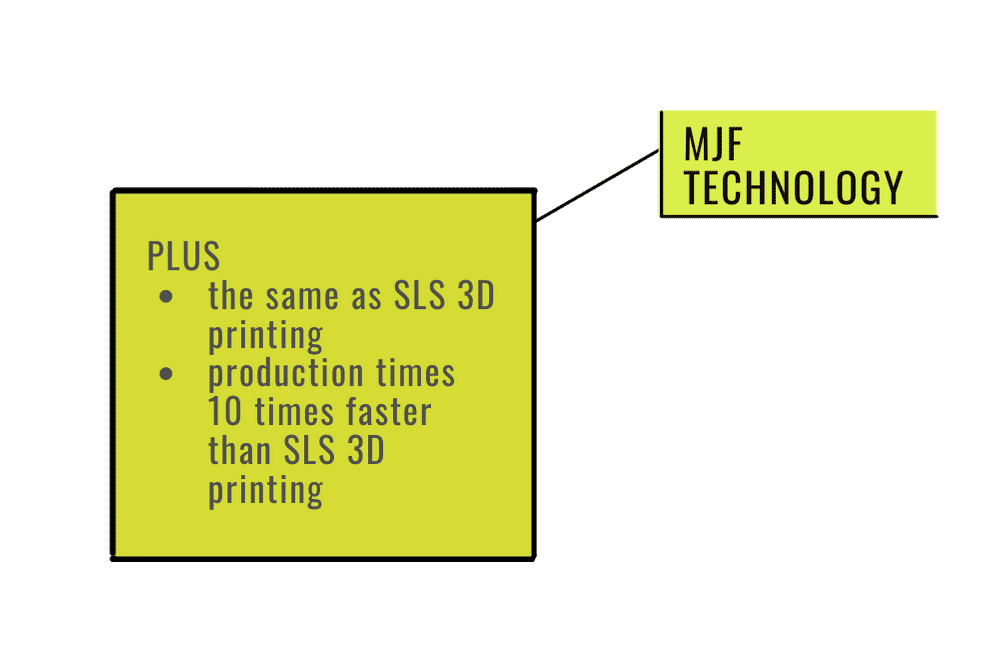

HP multi jet fusion (MJF) 3D printing technology is the best 3D printing technique for industrial production.

Printing is still done on a bed of nylon powder, but unlike its predecessor, in which the different dots are fused by a laser, MJF uses (patented) inkjet printing technology. The printer colours the various dots used to create the object black, then halogen lamps raise the temperature to 180 degrees and fuse the coloured dots. The non-coloured parts are not printed and will then be discarded.

The printing process is supervised by heat-sensitive cameras that keep the temperature of the printing booth uniform at all times. The advantages of this type of printing are the excellent precision and in addition a printing time 10 times longer than laser sintering.

PolyD has chosen MJF technology as its 3D printing service.

If you want to try out the advantages of this technique, upload your part to our Online Quote and enjoy 3D printing!