Hello engineers and 3D printing enthusiasts!

After the great success of the first season of PolyD-Lab, we are excited to present the second season!

Before we start with the prototype project, let us recall what PolyD-Lab is and the changes from the first to the second edition.

Ski Touring Pole Grip

What is PolyD-Lab

PolyD-Lab is our dedicated 3D printing lab, where we print free of charge and analyse projects that arrive at labpolyd@gmail.com

For more information, read our blog on the page "Your Part in MJF 3D Printing for Free".

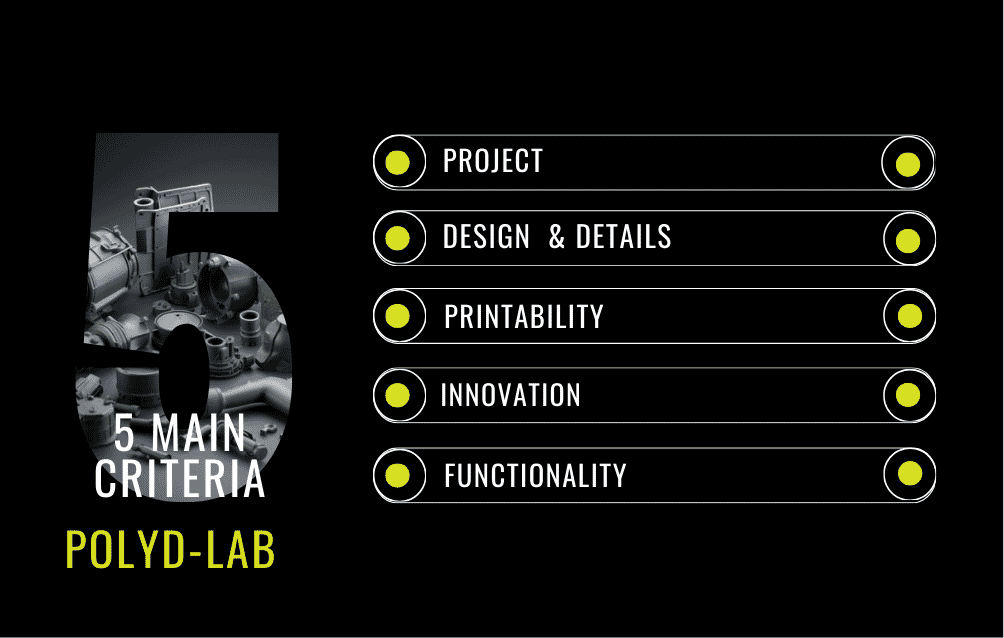

The analysis of the Parts and Components that are the subject of your proposals is carried out through the evaluation of 5 Fundamental Criteria, which we have further refined and enriched this year:

- Project,

- Design and Details,

- Printability,

- Innovation,

- Functionality.

Handle for Ski Mountaineering Poles

The piece selected for this competition is 'Grifo', a grip designed by Marcello Sgariboldi and Claudio Grassi for ski mountaineering poles.

Marcello, a firefighter and passionate mountaineer with a degree in motor sciences, got the inspiration for Grifo during a hike on Gran Zebrù. During this adventure, he noticed the difficulty in quickly reaching the ice axe, essential for safety in the mountains, and decided to solve the problem by contacting Claudio, an experienced CAD designer.

After several iterations, their project became a patented reality that even accompanied Italian mountaineer Marco Confortola during his ascent of Nanga Parbat in Pakistan, a mountain massif over 8000 metres high!

Project Design and Printing

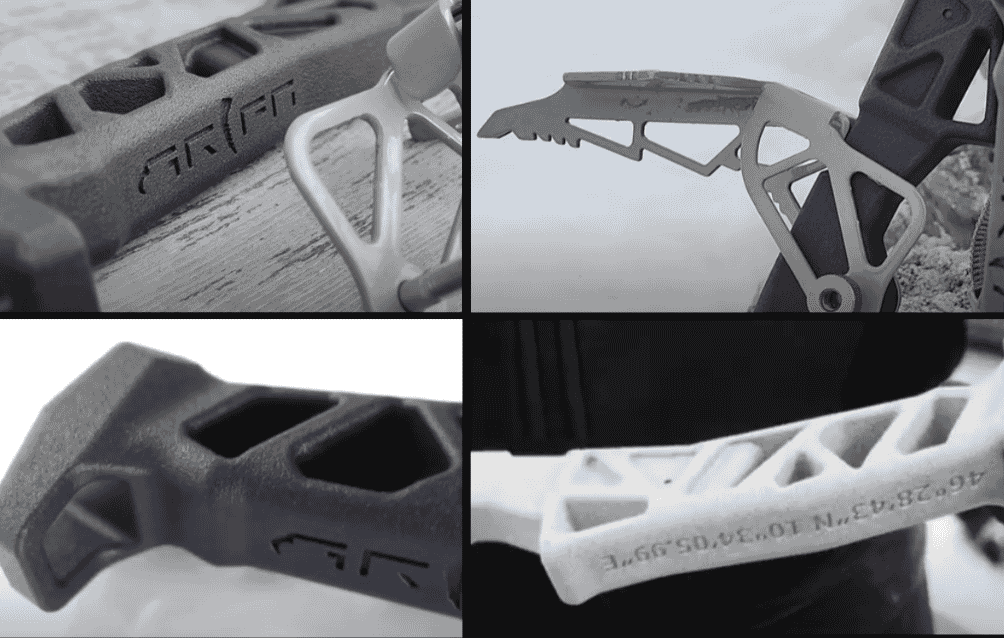

The main function of this 3D-printed piece is precisely that of having the ice axe at hand at all times, to assist in braking a fall as well as in ascending. Thanks to the possibility of prototyping, it was possible to perceive the finished product and also foresee possible modifications.

The project realised by Marcello, which is part of a larger project he has been working on with Claudio for a few years, has special features:

- thanks to 3D printing with PA12 nylon, the handle is extremely light;

- the 18 degree inclination of the handle favours grip and wrist mobility;

- the front hook (beak) allows ski bindings or boots to be hooked or unhooked;

- the housing of a special pick, an anti-slip device, which can be attached or removed if necessary.

Criteria Analysis

Project

This piece shows the expertise of an experienced engineer, with an ergonomic shape carefully designed to promote grip even when wearing gloves. Moreover, its ability to hold up to 200kg testifies to its solidity. (Rating: 4/5)

Design and Details

Grifo is customised with the name and coordinates of Gran Zebrù, with no edges that could create problems during use. The front slot is designed to facilitate the attachment of ski boots. (Rating: 4/5)

Mouldability

This design proved to be excellently mouldable, maintaining solidity and strength without deformation. Its structure allows the full potential of MJF printing and three-axis isotropy to be exploited. (Rating: 5/5)

Innovation

Grifo stands out for its innovativeness in solving a concrete problem, demonstrating the essence of MJF 3D printing. The fact that it was patented and accompanied a well-known mountaineer on his adventures attests to its success. (Rating: 5/5)

Functionality

This design effectively solves the problem of always having an ice axe at hand, making it essential for safety when climbing. (Rating: 5/5)

Conclusions

The grades awarded to Grifo are:

- Design 4/5,

- Design and Details 4/5,

- Printability 5/5,

- Innovation 5/5,

- Functionality 5/5.

The final grade, obtained from the average of the criteria (5), is 4.6, guaranteeing Grifo first place in the ranking!

Marcello and Claudio's prototyping work shows how 3D printing offers an efficient and functional way to create prototypes quickly. With its ability to transform digital files into physical objects, it allows engineers, designers and enthusiasts to test and refine their ideas quickly and accurately:

- it improves quality;

- development time and costs associated with producing traditional prototypes are reduced;

- the process becomes more interactive.

3D printing also makes it possible, as in this case, to create complex geometries otherwise impossible with conventional methods, and offers enormous flexibility in the design and development process.

For info on the GRIFO project you can contact Marcello Sgariboldi directly at the email address: marcello.sgariboldi@libero.it

If you too would like to try your hand at it, we are waiting for your projects. Use the e-mail labpolyd@gmail.com

Try our quality 3D printing and online quotation at PolyD.

Happy 3d printing!