Hello Engineers!

Welcome to PolyD's new video on Professional 3D Printing.

Today we are going to take a closer look at Build Cooling, i.e. the cooling of 3D Printed Parts using MJF Technology.

Why is this phase of Industrial 3D Printing important? Because it has a significant impact on:

- mechanical parameters

- internal tensions of the material

- deformation or "bending" of the printed part.

3D MJF Printing: Natural Cooling or Fast Cooling?

As you have already seen in our previous video dedicated to MJF printing, i.e. in the second episode of Professional MJF 3D Printing, the phase immediately following 3D Printing is the cooling of the Build.

PREVIOUS PRINTING STEPS

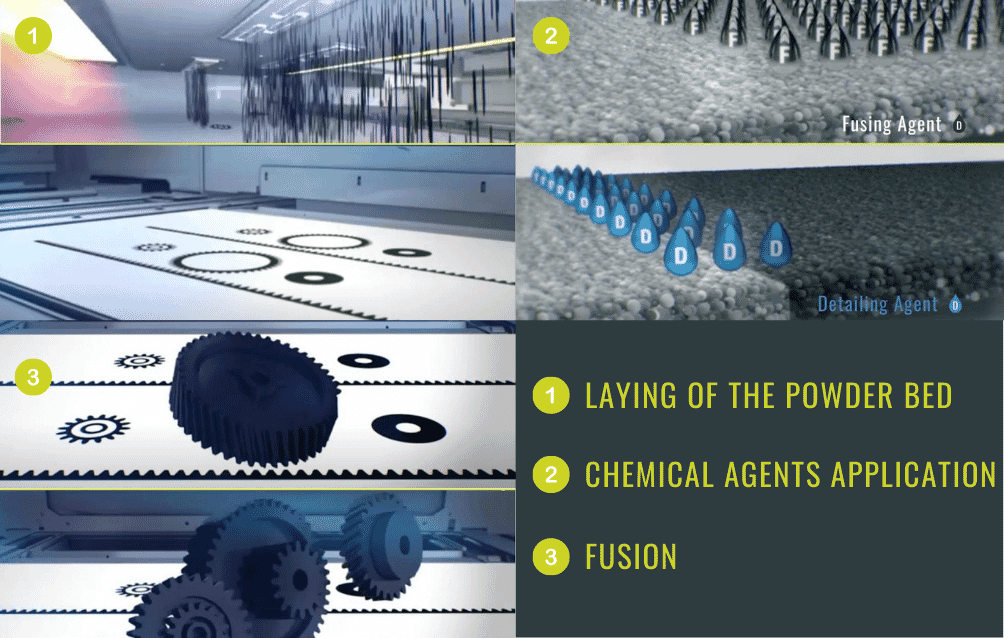

Let's put the exact point we are at in the 3D Printing process into context: this is the final stage related to:

- Laying of the powder bed;

- Application of chemical agents;

- Melting.

This is the moment when the powder is spread over the build area in layers, on which the fusion and detailing agents are subsequently cast.

The fusing agent absorbs the energy emitted by the lamps and causes the powder to heat up, while the detailing agent evaporates, preventing the adjacent, non-fusing powder from overheating. This process causes an abrupt temperature transition, resulting in a melt with distinct and precise edges, and causes the Build's nylon powder to accumulate a significant amount of energy in the form of heat.

The temperature of the Build during printing is maintained at a constant 180 degrees C. At this temperature the part already has its shape, but is actually still malleable and deformable, like the "Play-Doh effect". The Nylon powder must then disperse this energy until it reaches room temperature in order to guarantee the final mechanical characteristics of the Prototype and solidify its shape.

Cooling of the parts

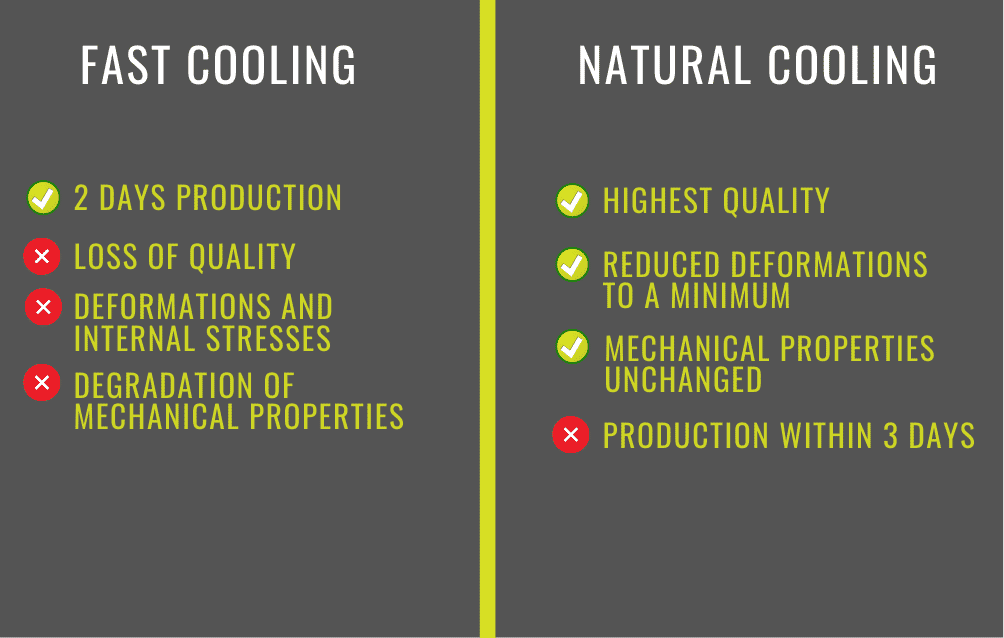

The cooling process can take place in two modes, Natural or Fast:

- Natural Cooling;

- Fast Cooling.

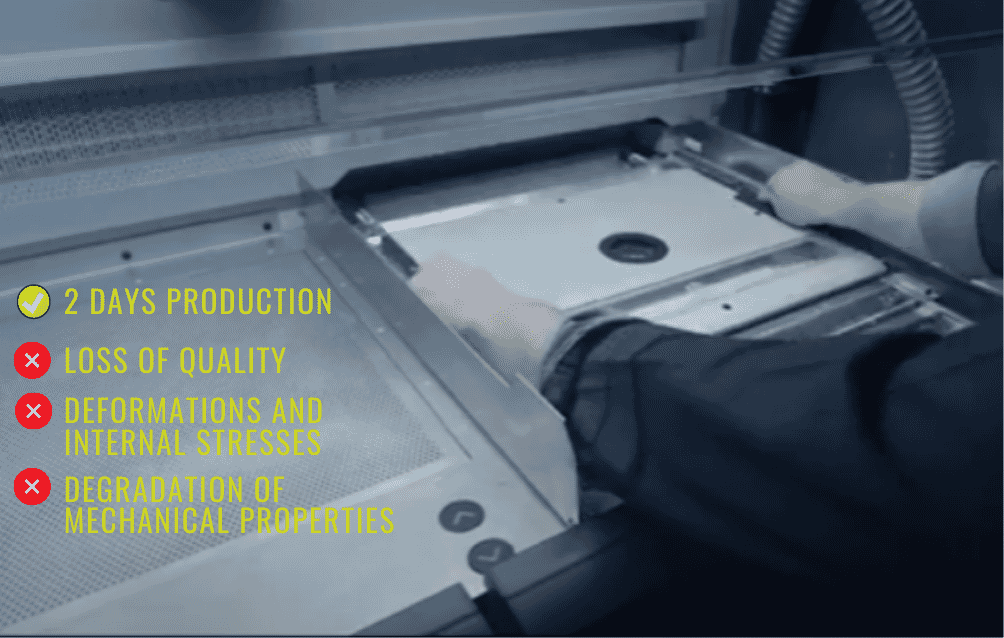

FAST COOLING

Fast Cooling is an accelerated cooling process that takes place directly inside the Build Unit. It allows the transition to unpacking operations after printing and lasts on average from 4 to 6 hours. Its sole purpose is to bring the contents of the Build Unit back to room temperature and it does this with the aid of forced ventilation. The advantage of this process is therefore the shortening of production times so that the components can be delivered within 3 working days.

And so far we have talked about the advantages. But what are the disadvantages?

Nylon is a plastic polymer and all plastics are very poor conductors of heat. If you force the temperature reduction process, you get uneven and uneven cooling of your Parts or Prototypes, which may lead to stresses and deformations of the 3D printed objects. Our experience also shows that the mechanical properties are adversely affected.

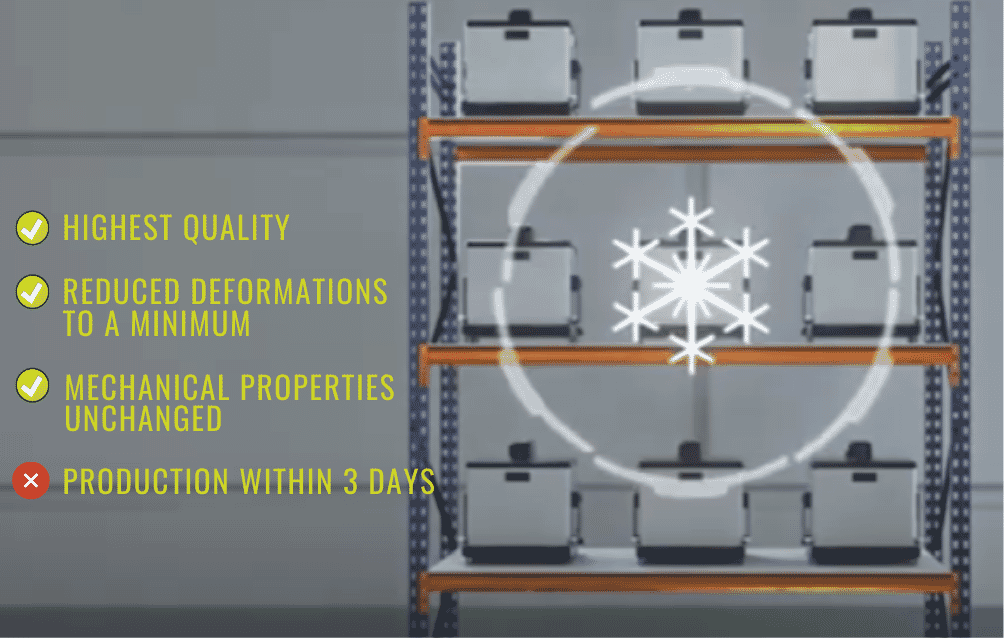

NATURAL COOLING

Natural Cooling is the natural cooling process.

All the powder and parts inside the Build are transferred into the Natural Cooling Unit, automatically in a single block, to avoid thermal shocks to the individual components. From then on, all the nylon contained in the Natural Cooling Unit releases its heat to the environment in a natural way.

The process takes 48 hours and allows for the best quality result - mechanical and structural - of MJF-moulded objects.

Final Conclusion

We come to the answer to the question in the title. Is it possible to get a quality part in MJF in less than 3 days?

In our opinion, the answer is no. The technical risks involved in Fast Cooling are too great to guarantee a high level of quality.

For these reasons we at PolyD propose a minimum production time of 3 days, which allows the best performance with MJF 3D Printing technology.

If you want to try to print your Parts and Prototypes with us, or if you are a 3D Printing Service and want to provide the best service to your customers, take advantage of the welcome offer you can find in the PolyD Online Quote.

Happy 3D Printing!