Hello Engineers!

Welcome to this new video about 7 things you probably don't know about Online 3D Printing.

The latest generation of 3D printers are used in many sectors to make Robust, Functional and Affordable Parts and especially to speed up production: in industry, medical and fashion and also to support the environment.

7 Interesting Facts about 3D Printing

Fact #1: Airplanes do rapid prototyping of 3D printed parts

The world-famous aircraft company BOEING was one of the first companies in this sector to make 3D printed prototypes, and after years of design and experimentation the Boeing 777X successfully completed its first long-haul flight in early 2020, using 3D printed metal parts.

What is particularly remarkable about this aircraft from the US giant is that its two GE9X engines incorporate several 3D printed metal parts including low pressure turbine blades made from a titanium alloy. The 3D printed blades rotate inside the engine 2,500 times per minute, withstanding extreme conditions such as heat and forces.

Fact No. 2: The 3D Printing Service could be the answer to recycling plastic waste

3D printing already contributes significantly to the well-being of the environment, thanks to efficient processes that produce no waste. With professional 3D printing you can produce objects while saving CO2 locally compared to other technologies, which are centralised and work by subtraction.

While industrial processes discard large amounts of material to create parts, with 3D printing the component is built according to specific needs and at the place where it is needed. This also eliminates emissions from post-production transport.

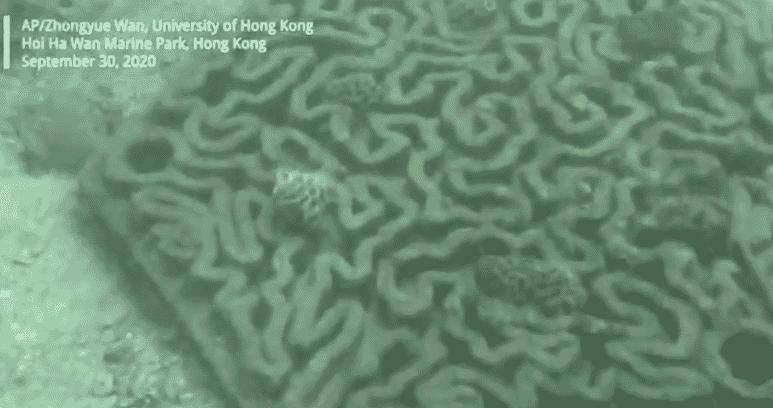

Fact #3: 3D printing has produced prototypes to rebuild part of the coral reef

Global warming is one of the biggest problems our planet is facing, our oceans are dying and along with them a wide range of marine biodiversity. To tackle this problem and save the coral reefs off the city's coast, marine scientists at the University of Hong Kong have developed a new method with the help of professional 3D printing.

In the Hoi Ha Wan Marine Park, researchers have placed specially designed, 3D-printed terracotta tiles in order to create artificial reefs.

Fact No. 4: BMW Group has an industrial 3D printing plant for additive manufacturing, costing more than EUR 15 million

This facility was designed with the intention of industrialising 3D printing and reducing the production time for part of the manufacturing processes. The campus brings together BMW's prototyping, production of series parts, research into new 3D printing technologies and training centres under one roof.

Fact no. 5: The world of medicine is benefiting greatly from rapid prototyping with 3D printing

The opportunities offered by 3D printing in the medical field range from creating customised prostheses, reproducing organs for educational purposes, making dental appliances, aligners and surgical guides from biocompatible materials, to applications to help healthcare workers fight Covid-19, such as creating comfortable face shields.

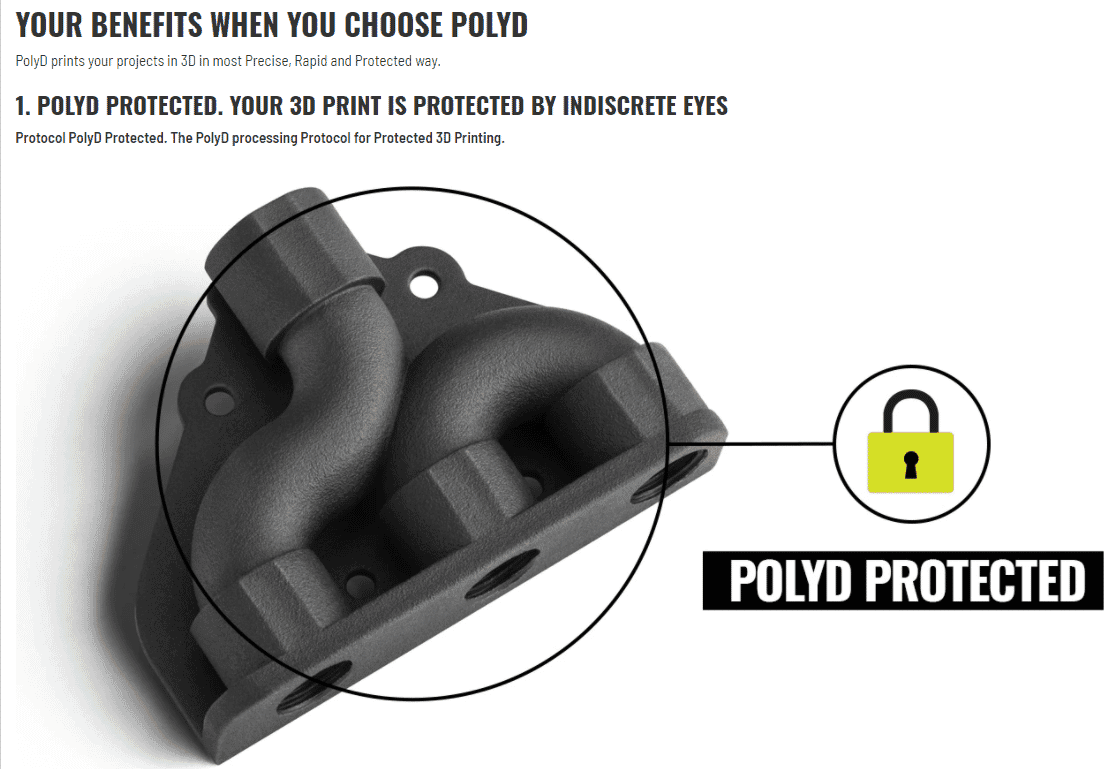

Fact No. 6: When making prototypes, it is really very important to keep your designs safe

As for every creator and artist, it is also necessary for those who create 3D files to protect their designs by means of patents or even just by paying the utmost attention and care in sending their files, if necessary, only to serious and reliable third parties.

At Polyd, for example, we give our customers the possibility to upload their files only after logging in to their private area, we can also sign a confidentiality agreement (NDA) and we never publish photos of parts printed on behalf of our customers without their consent.

For more information read our blog article or go to the Confidentiality Protocol page of our website.

Fact #7: 3D printing in fashion is used to create components, parts and accessories, build prototypes, production tools and expand customisation options

Instead of 3D printing entire garments, 3D printers in fashion are used to integrate parts of an entire design, such as embellishments, accessories and buttons. Small end-use accessories can be easily assembled in minutes or hours using 3D printing. Materials with a flexible nature, such as TPU, can be used to add unique accent pieces or embellishments to the garment itself.

If you know of any other curiosities and would like to tell us about them, you can do so by writing to hello@polyd.it

Hello everyone and Happy 3D Printing!