The main objective of Industrial Design is to improve people's lives by offering products that are both useful and aesthetically pleasing. In this article, we discover how Industrial MJF 3D Printing can support the creative and design process of industrial designers, home designers and object designers.

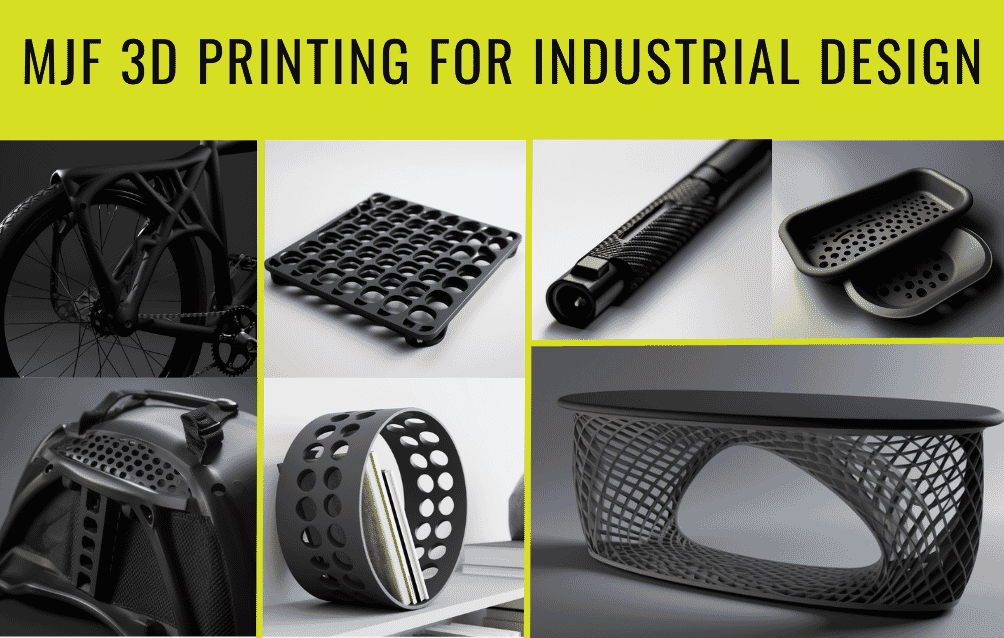

MJF 3D Printing for Industrial Design

Design Objects represent the meeting of aesthetics and functionality; they transform spaces and create engaging visual and sensory experiences through appealing shapes and innovative solutions. Aesthetics is not the only element of value in Pieces or Prototypes; other aspects are functionality, ergonomics, usability and the demands of identity and personality. Design objects are designed to simplify life by offering practical and intelligent solutions to our everyday needs. They can represent innovation and technological progress; designers and engineers often work together to create Prototypes and Objects that exploit the latest scientific and technological breakthroughs. The integration of advanced materials, the use of new production techniques and the implementation of interactive components are just some of the features that make industrial design cutting-edge.

The Benefits of 3D Printing in Industrial Design

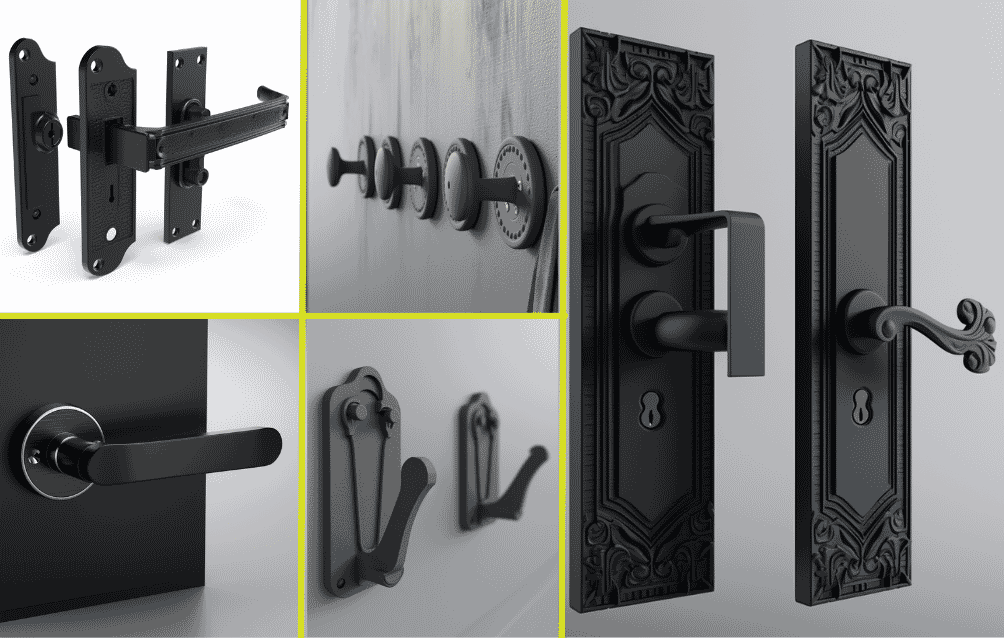

If you are involved in industrial design, you know that your job mainly involves the design of physical products, such as appliances, lighting elements, furniture, vehicles, technological devices, spare parts or components and precision parts. Your work includes research, conceptual design, prototype development and collaboration with engineers for series production.

3D printing MJF (Multi Jet Fusion) has opened up new horizons in the field of design and prototyping, allowing you to create unique design Parts, Prototypes, Accessories and Complements with amazing precision and quality. Here's how MJF 3D printing challenges the limits of traditional design and can intervene and facilitate your creative process:

1. Exploration of ideas

MJF 3D printing allows you to explore ideas quickly and tangibly. You can transform concepts into physical models and evaluate shapes, proportions and spatial interactions more immediately and effectively. Regardless of the type of design software you use, remember to export .step .stl formats as print files. You can also use our online converter or read in our blog everything you need to know about controlling print files and how we can support you.

2. Rapid, customised prototyping

Quickly create working prototypes of your designs. You can transform digital models into physical objects whose shapes, dimensions and functionality you can evaluate before moving on to series production. You thus accelerate the product development process, reducing time-to-market with faster iteration.

MJF 3D printing also enables the production of customised components. You can adapt your designs to meet specific customer needs, with unique, customised products that perfectly match individual preferences or sector-specific requirements.

3. Wide choice of materials and finishes

You can use a wide range of materials and finishes to create design objects: different types of plastic, rubber, nylon and even advanced composite materials. This allows you to explore new characteristics and properties, such as transparency, flexibility or strength, and opens up new horizons in the design of objects with advanced mechanical properties. You can thus experiment and create products with specific characteristics, such as flexibility, strength or transparency.

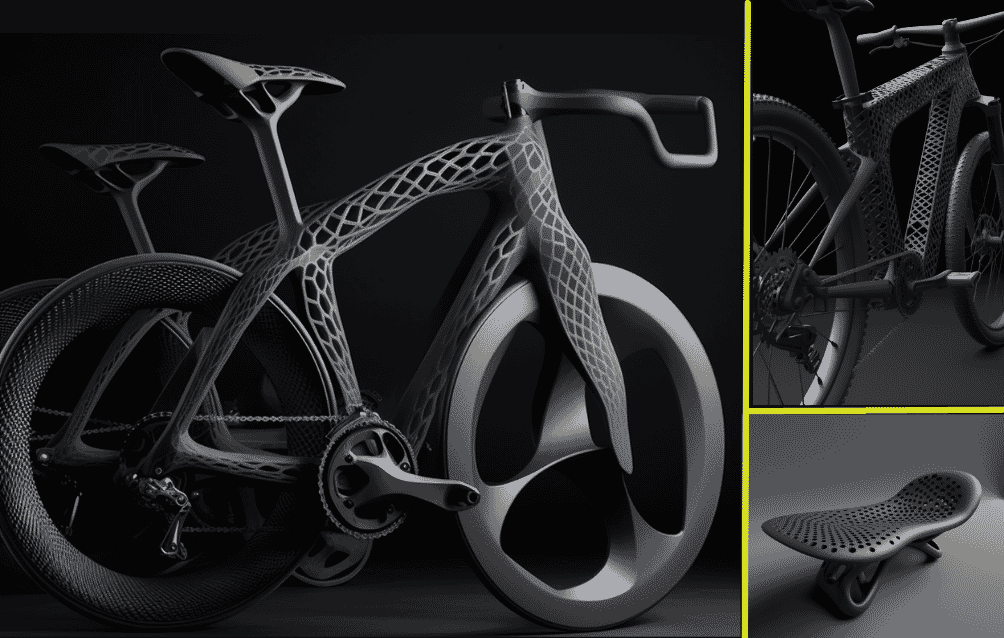

4. Extraordinarily precise details

Online MJF 3D printing allows you to reproduce complex geometries and extraordinarily precise details that would be difficult to achieve with traditional production methods, thanks to its ability to deposit the bonding agent in a controlled manner. Another advantage of MJF 3D printing is the ability to incorporate internal moving parts, such as functioning mechanisms, into prototypes of complex objects, which can be tested and evaluated for their efficiency and practicality. This is a particular advantage if you are an industrial designer or an engineer, because you can use MJF 3D printed prototypes to analyse and optimise your designs before mass production and explore innovative shapes and advanced functionalities that break through the limitations of conventional manufacturing processes.

5. Optimising the production process

One of the main advantages of MJF 3D printing is the speed of production; you reduce the time and costs associated with the production of objects and can go directly from the design phase to the production of working prototypes quickly and efficiently, without the need for specialised equipment or expensive moulds or even complex assembly processes. This makes the development process more streamlined and allows you to focus on creativity and innovation. Finally, MJF Industrial 3D Printing offers greater sustainability than traditional production methods. By reducing material waste and energy use, this technology contributes to optimised and more eco-friendly production, reducing the environmental impact of design and prototyping processes.

Conclusion

In summary, MJF 3D printing has transformed the creative process for designers, allowing you to explore ideas quickly and tangibly, customise your designs, experiment with advanced materials, incorporate complex details and optimise the production process.

If you too would like to try your hand at producing Objects, Prototypes, Complex Components and Design Pieces, try our Online Estimator now and take advantage of our Free First Order offer.

Happy 3D Printing!