Hello Engineers!

Today we analyse the Pros and Cons of 3 3D Printing technologies, FDM, MJF and Injection Molding, using the Pump Body Prototype as an example. Our comparison considers the analysis of 6 characteristics: quality of the parts produced, processing time, materials used, availability of information on the web, production costs and investment and plant costs.

FDM VS MJF VS INJECTION: The pros and cons of 3D printing technologies

What is meant by FDM, MJF and Injection Moulding?

Let's quickly review what is meant by FDM, MJF and Injection Moulding.

FDM is one of the most popular 3D printing techniques on the consumer side of the market, and is known as Fused Deposition Modeling, because it extrudes filaments of material and deposits them on top of each other, layer by layer, on the surface. This technology uses 3D desk printers.

MJF is the best 3D printing technique for the industrial production of Prototypes, Parts and also for Serial Objects. It starts with a bed of nylon powder; the printer colours the dots needed to create the object, which halogen lamps then melt to create the Components.

Injection Moulding involves injecting molten plastic material at high pressure into a closed mould. The mould is then opened when the object solidifies.

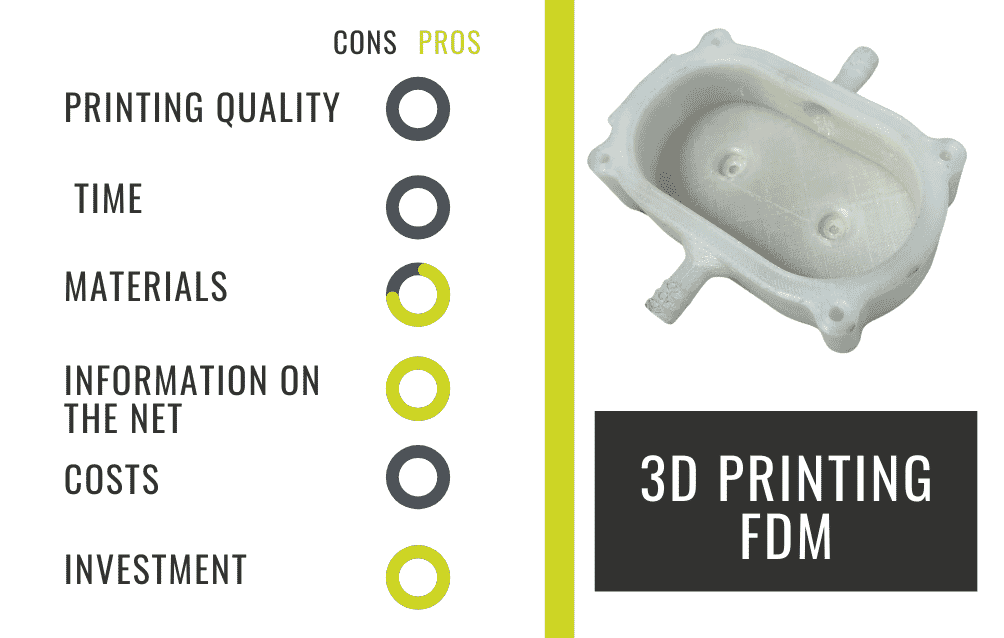

3D PRINTING WITH FDM TECHNOLOGY

PROS

- INVESTMENT: as far as investment costs are concerned, this printing technology uses "entry level" printers with a very low cost; with a few hundred euros you can take home a printer. The quality can be improved by purchasing printers of an increasingly professional level.

- MATERIALS: FDM technology has a wide range of materials:

- polylactic acid, or poly lactic acid or polylactate (PLA);

- PPS, a semi-crystalline thermoplastic polymer;

- polyethylene terephthalate (PET);

- the acrylic filament polymethyl methacrylate (PMMA);

- Polycarbonate (PC),

- Polypropylene (PP);

- Thermoplastic Polyurethane (TPU);

- and Acrylonitrile-butadiene-styrene plastic (ABS).

- INFORMATION ON THE NET: there is a wealth of information, video tutorials, courses and all kinds of updates; it is virtually impossible not to find what you are looking for.

CONS

- PRINTING QUALITY: layers are often quite visible on the object and in order to have a smooth surface it is necessary to sand afterwards. Furthermore, the mechanical properties of the Z axis are always inferior to those of the other two axes, i.e. the X and Y axes.

- PRODUCTION COSTS: In FDM printing, the cost of the media has an impact on the total cost of the components, especially if you want to produce unusual objects or objects with overhanging shapes.

- PRODUCTION TIME: these are among the longest: it takes days to print 3D parts.

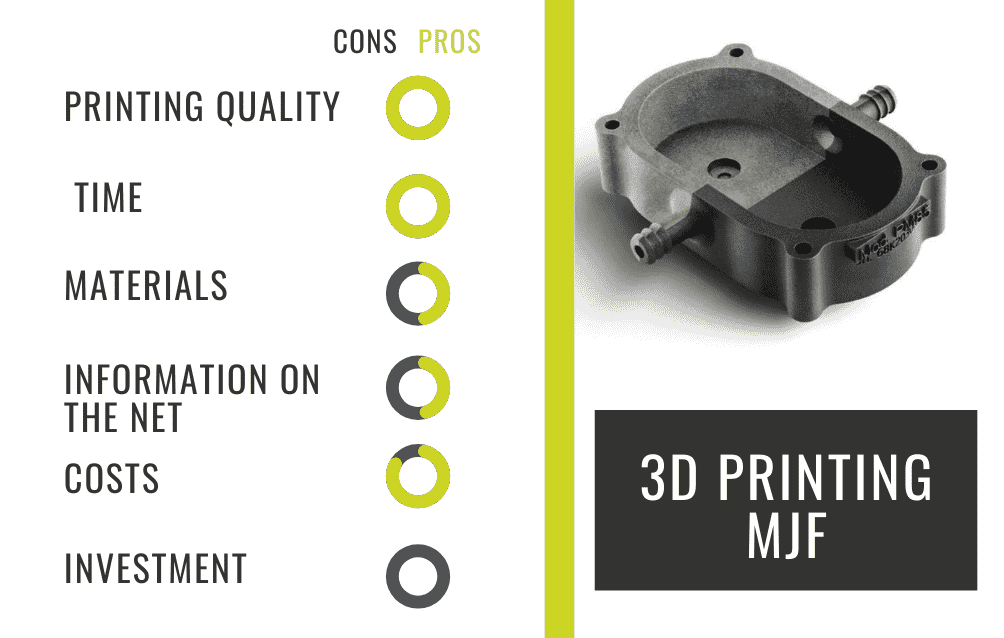

3D PRINTING WITH MJF TECHNOLOGY

PROS

- QUALITY: it is among the best on the market. You can obtain prototypes with a tolerance of 2 tenths of a millimetre. Moreover, the mechanical capacity is identical on all three axes: X, Y, Z, comparable to the same object printed by injection.

- TIME: MJF is currently the fastest industrial 3D printing technology for the production of mass-produced objects; for example, it takes only 10 working hours to print 100 pieces of the pump body you see in the picture.

- COSTS: You can print mass-produced objects and prototypes at very competitive prices and there are professional 3D printing services such as PolyD, which can provide all the necessary information and production support.

CONS

- INVESTMENT: the initial investment has the cost of an industrial plant, it is not an activity that can be managed with low printing volumes.

- MATERIALS: the range of materials available is more restricted, there are:

- the Polyamide PA11;

- the technopolymer (polyamide) also called PA12, PA12 Fast and PA12 Top Mechanical;

- Rubber-like (TPU);

- Polypropylene;Glass-filled PA12, also called PA12GB.

- INFORMATION ON THE NET: since it is a recent and innovative technology, there is little information available on the net, either about the process, the guidelines to follow for printing, or the various criticalities that can be generated during the production process (read our article on the 5 STL file errors in 3D printing).

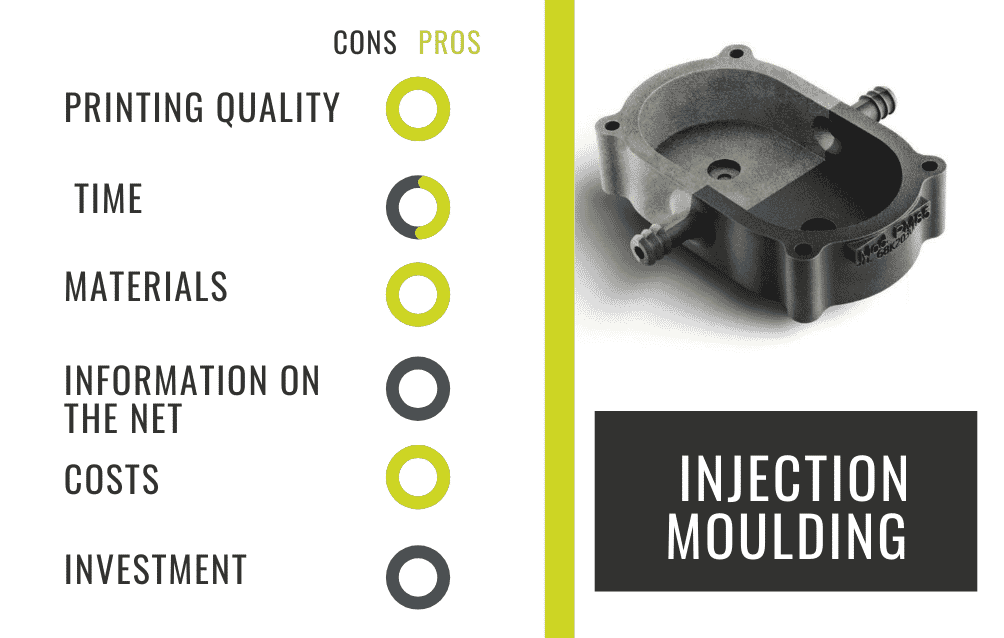

INJECTION MOULDING

PROS

- COSTS: it is the cheapest technology for the mass production of objects, net of the initial cost of the mould.

- MATERIALS: there is a very wide range of materials to choose from, depending on your needs.

- QUALITY: it is the reference technology for the production of plastic objects.

CONS

- INVESTMENT: it is the most classic way to mould a plastic object, but the industrial plant costs are high.

- TIMES: it takes months to create the initial mould and it is then almost impossible to make changes or updates to the mould already made.

- INFORMATION ON THE NETWORK: since it is an industrial process, the technical knowledge is in the hands of the companies using this technology.

You can see our advantages for yourself; get a quote for a rapid prototyping in 3D printing through our Online 3D Printing Quote. The estimator accepts .STL .STEP .STP files and if you want to do a conversion first, there is our step into stl converter.

Happy 3D printing!