Hello Engineers!

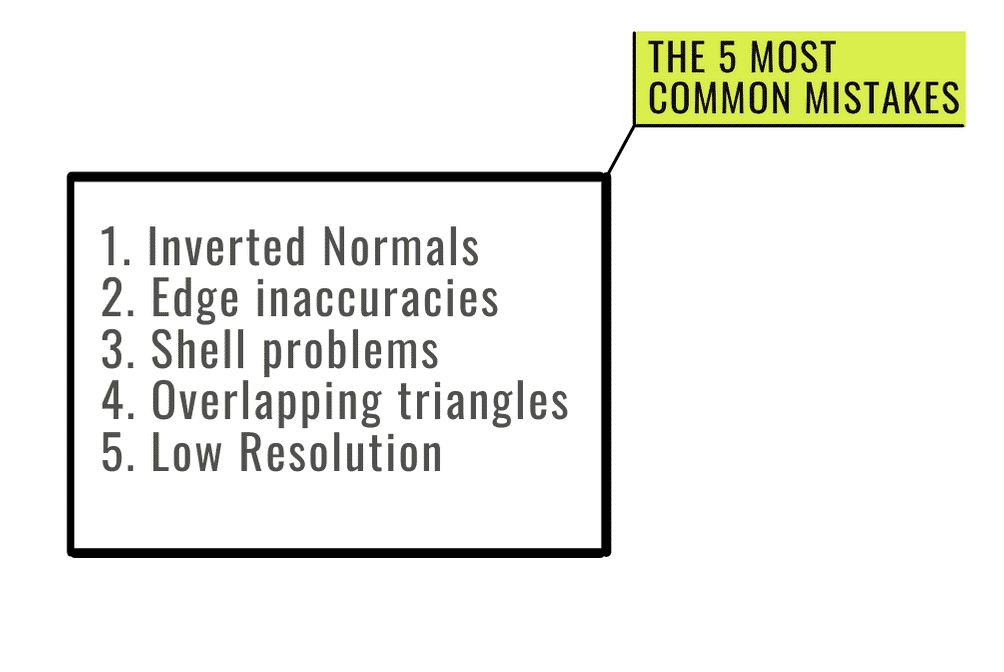

You may have done some 3D printing and found that the result was poorly defined, had small defects or even failed to finish the print. This can be due to the STL file because of small imperfections, or the way it was exported. In this video we discuss the 5 most common mistakes that can happen on an STL file and how to correct them.

THE 5 MISTAKES NOT TO MAKE WHEN 3D PRINTING STL FILES

There are many different approaches to 3D modelling, many materials that can be used, and on top of that, printing technologies are constantly evolving. For these reasons, mistakes can be made when 3D printing an STL file.

WHAT IS AN STL FILE?

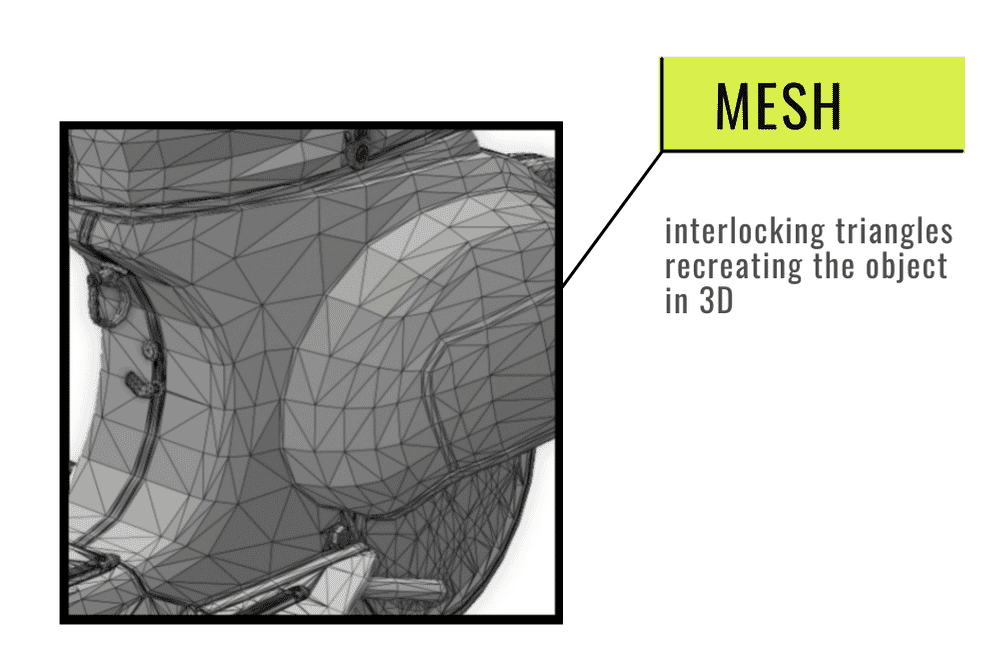

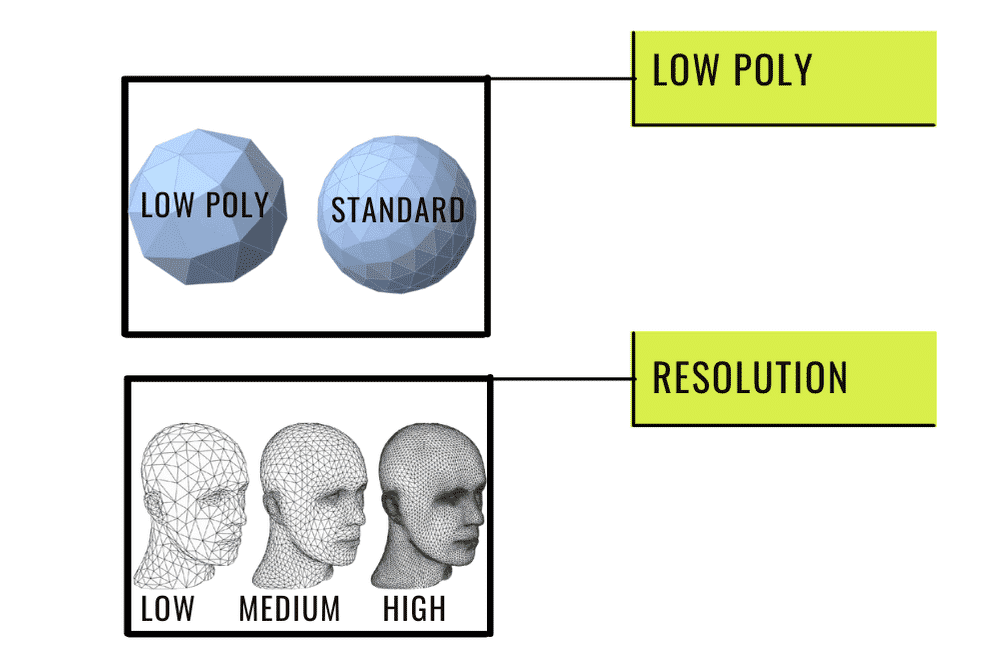

As many people are approaching 3D printing, it is becoming increasingly common to create and export an STL file. The STL file is the most commonly used file format for 3D printing. Its acronym stands for "Standard Tesselation Language" or "Stereolithography". It describes the geometry of a 3D object without applying any colour, texture or other attributes. This file uses a series of interlocking triangles to recreate the 3D object: the more triangles, the higher the resolution. Interlocking multiple triangles is commonly referred to as Mesh.

Why not use a classic CAD file?

CAD files are often saved in a proprietary format, which makes them difficult to use with all software. STL files, on the other hand, are an open format and can therefore be read by most software that interfaces with printers.

THE MOST COMMON ERRORS IN STL FILES

Why do errors occur? Some premises

# PRECONDITION 1: Many errors are related to the export from the CAD file to the STL file. This process converts the parametric modelling of the object into a surface representation called Mesh. The export is therefore the most delicate phase, because many CAD files are generated by software that is not designed for Additive Manufacturing applications.

# PRECONDITION 2: In addition to the conversion, there may be small inaccuracies in the original design and this may lead to a lower definition of the various triangles.

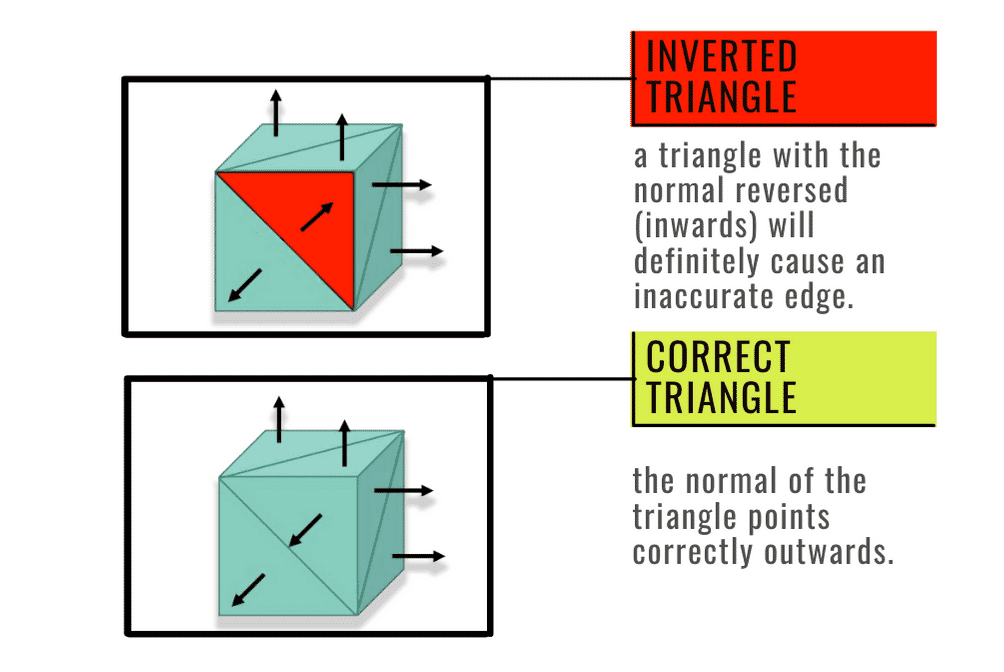

ERROR 1: INVERTED NORMALS

Normals are vectors perpendicular to the planes of the triangles that make up the mesh. They define the direction of the plane and this helps the printer to understand which is the outside of the surface and which is the inside. The normal of the red triangle points inwards instead of outwards. In this case the triangle, commonly called the Inverted Triangle, has the normal reversed and can cause an inaccurate edge.

ERROR 2: EDGE INACCURACY

Edge Inaccuracy includes errors in edges and planar holes.

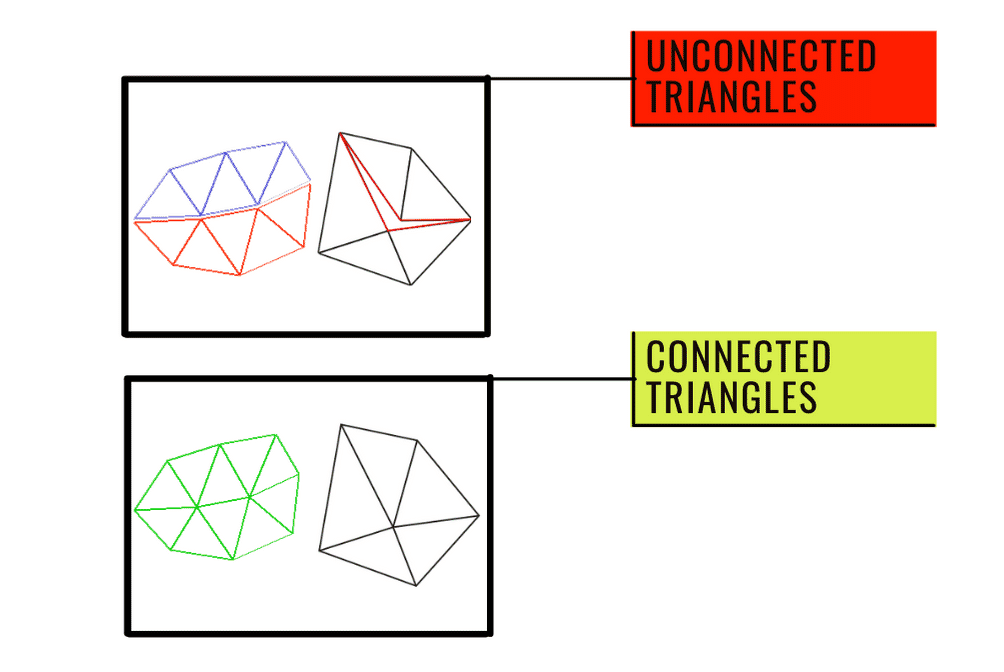

It is possible that an edge of a triangle is not well connected or there are missing triangles. In this case the edges are inaccurate because they are discontinuous or planar. This happens when the triangles are not perfectly connected to each other; the problem is easily solved by correctly connecting the edges of the triangles.

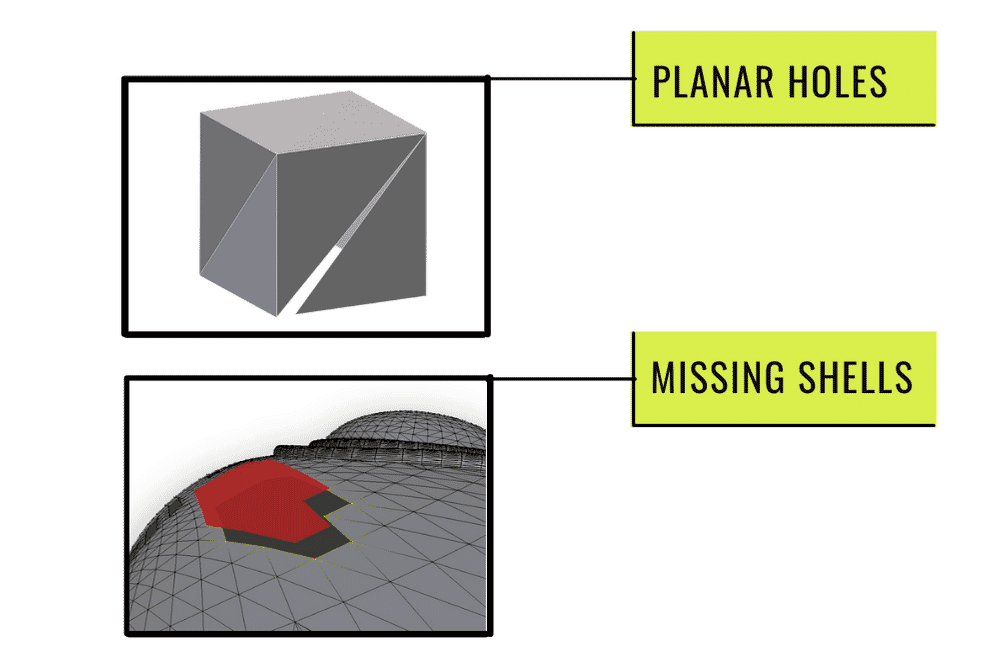

Planar holes, on the other hand, are triangles that are connected together to create a hole. This happens when triangles or parts of shells are missing.

ERROR 3: PROBLEMS WITH SHELLS

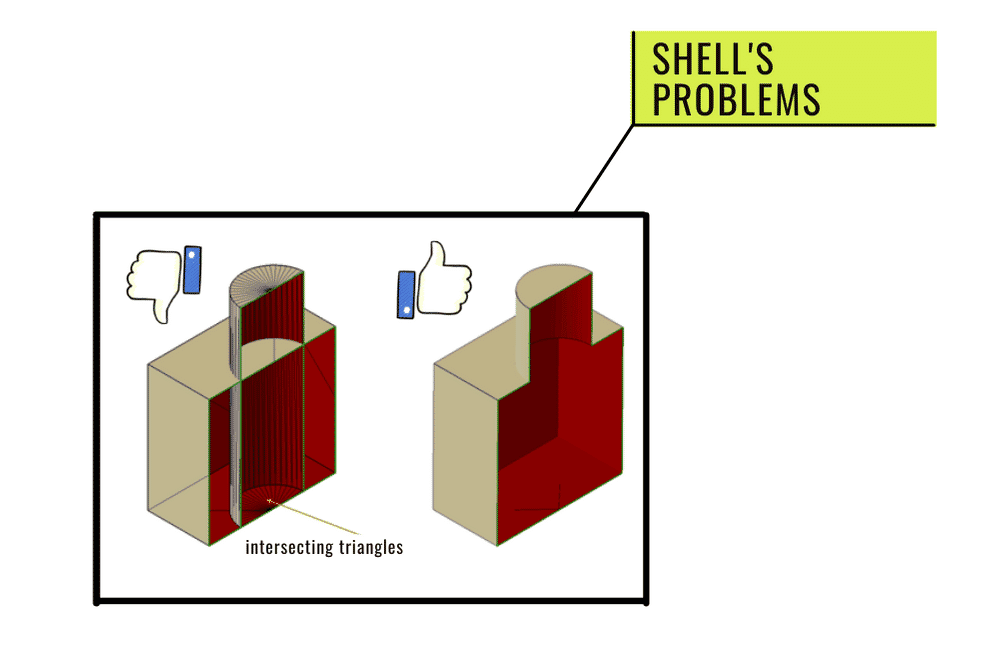

The shells we are talking about are the agglomeration of triangles that create a part of the model. Overlapping of these shells is a common mistake and can create problems in the slicer. This is because the printer will settle the same material in the same position twice.

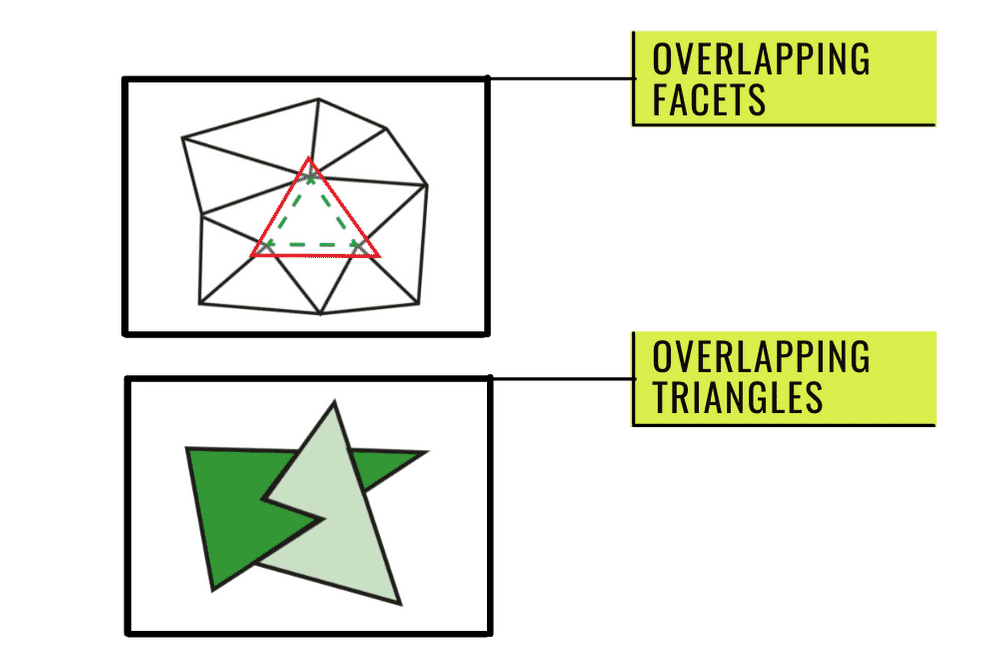

ERROR 4: SUPERPOSITION OF TRIANGLES

Si verifica quando la distanza o l'angolatura tra due triangoli è minore del valore che abbiamo dato alla tolleranza. Questi triangoli portano ad una superficie a zig zag. E' un errore meno cruciale degli altri relativamente alla stampabilità, ma migliorarlo potrebbe migliorare di gran lunga la qualità del tuo oggetto stampato.

ERROR 5: LOW RESOLUTION

In this case it is the low resolution with which we create our STL file. If the export is done with too low a resolution, triangles will be visible on the surface of the print. From an aesthetic point of view, this is not the best, but if desired, it can be used as an effect to create "Low Poly" objects, i.e. with a slightly digital look.

CONCLUSIONS

Increasing the resolution of STL files creates more triangles on the surface and the object will have better definition, but also a larger STL file size. Increasing the resolution beyond a certain limit is of no benefit. Very small details struggle to be printed.

Do you need to convert STEP files to STL? Try our free online converter!

With the MJF technology we at PolyD can guarantee an accuracy of 2 tenths of a millimetre.

Try PolyD and enjoy 3D printing!